- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

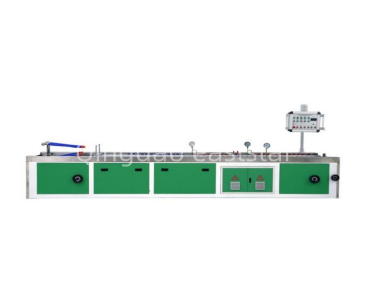

SPC Stone Plastic Flooring Production Line

Choosing Qingdao Eaststar means choosing a reliable partner. Our SJSZ-65/132 SPC Stone Plastic Flooring Production Line has served numerous manufacturers and has received high praise for its superior stability. The fully automated design, coupled with branded components, ensures easy production startup. We not only deliver a high-quality profile production line, but also provide comprehensive services from installation and commissioning to process support, safeguarding your production.

Model:SZ-65/132 conical twin-screw extruder

Send Inquiry

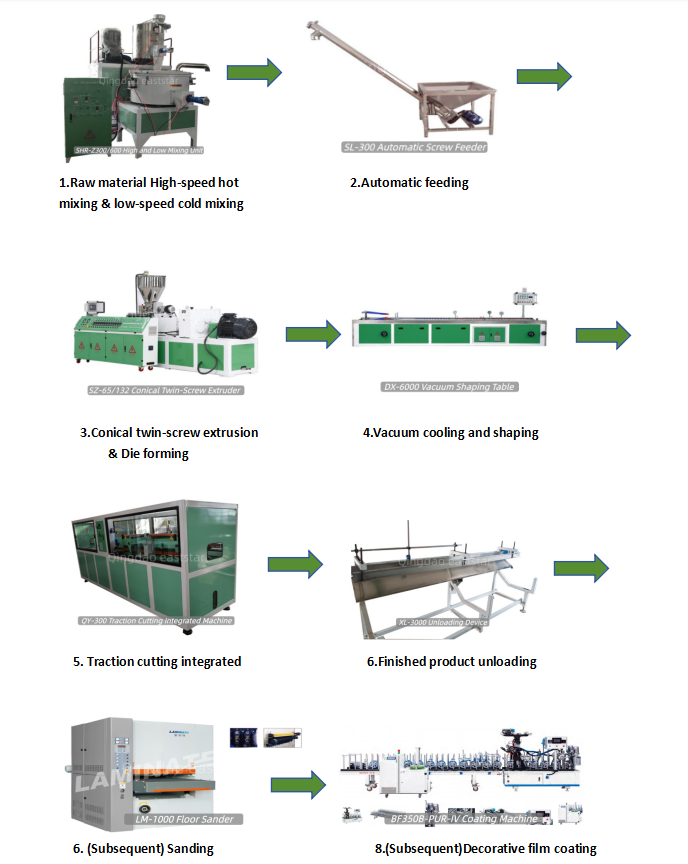

Overview of SPC Stone Plastic Flooring Extrusion Production Line

Eaststar's SPC Stone Plastic Flooring Production Line is the core equipment for producing high-quality stone plastic composite (SPC) flooring and profiles. This complete solution achieves full automation from raw material mixing, conical twin-screw forced extrusion, vacuum shaping to automatic cutting and collection. The core of the production line, the SZ-65/132 conical twin-screw extruder, ensures a dense and uniform core layer in the flooring through its efficient plasticizing and stable output. As a popular extrusion solution in the market, manufactured in our own factory, it has become the preferred choice for many flooring manufacturers due to its superior reliability and cost-effectiveness.

Complete SPC flooring production line equipment list

| Equipment Composition | Specifications and Models | Quantity | Core Notes |

|

Core of the whole line |

SZ-65/132 Conical Twin-Screw Extrusion Line |

1 set |

Includes automatic feeding, vacuum shaping,traction cutting, and unloading devices. |

| Matching molds | PVC-159MM floor mold | 1 set |

Customization based on customer needs |

| Matching molds | PVC-189MM Floor Mold | 1 set |

Customization based on customer needs |

|

Auxiliary equipment |

SHR-Z300/600 Highand Low Temperature Mixing Unit |

1 set |

Achieve efficient mixing and conveyingof raw materials |

|

Post-processing equipment |

LM-1000 Sander | 1 set |

Used for thickness setting and fine sanding of floor surfaces |

|

Post-processing equipment |

BF350B-PUR-IV Coating Machine |

1 set |

Achieve high-quality application of decorative film |

Key Features of Eaststar SPC Stone Plastic Flooring Production Line

Powerful and efficient plasticizing: The core adopts the SZ-65/132 conical twin-screw extruder, with twin screws rotating synchronously in opposite directions. It has forced feeding and self-cleaning functions, which has excellent plasticizing effect on SPC powder formulations and high output efficiency.

Reliable operation : The screw barrel is made of 38CrMoAlA alloy steel and undergoes deep nitriding treatment, resulting in high hardness and extremely strong wear resistance; the gearbox and distribution box gears are made of 20CrMnTi carburizing and grinding process to ensure high torque transmission and low noise operation.

Fully automated control: The entire production line achieves seamless integration from automatic feeding, extrusion, vacuum shaping, traction cutting to unloading. The control system uses international brand components such as Siemens, Omron, and ABB to ensure precise operation and reliable performance.

Exceptional Precision: The 6-meter-long vacuum forming table is equipped with multiple vacuum systems and water cooling to ensure uniform cooling and dimensional stability of the sheet metal. The integrated traction and cutting machine uses dual-track traction and alloy saw blade cutting to guarantee precise product length and clean cuts.

One-stop solution: We not only provide the main extrusion line, but also provide high-efficiency high and low mixing units, precision sanders and high-configuration PUR coating machines, providing customers with a one-stop turnkey project from raw materials to finished flooring.

SPC Stone Plastic Flooring Production Line Core component Technical Details

A. Core Product Line: SJSZ-65/132 PVC Stone Plastic Flooring/Profile Production Line

| Component Module | Key parameters | Specifications and Instructions |

| 1. SL-300 Automatic Screw Conveyor | Conveying capacity | 300 KG/h |

| Bin volume | 200 KG | |

| Motor power | 1.5 KW | |

| 2. SZ-65/132 conical twin-screw extruder | screw diameter | Φ65/Φ132 mm |

| Screw rotation | Synchronous outward rotation | |

| Screw/Barrel Material | 38CrMoAlA, nitrided, hardness > HV740/>HV940 | |

| Main motor power | 37 KW (Shandong Hengli/Qingdao Electric Machinery) | |

| Speed adjustment method | ABB Variable Frequency Speed Control | |

| Heating power | 24 KW (cast aluminum heating coil) | |

| Cooling method | Centrifugal fans (3 units × 0.25kw) | |

| Gearbox gears | 20CrMnTi, carburizing and quenching gear grinding process | |

| 3. Twin-screw feeder | Feeding method | Automatic twin-screw metering conveyor |

| Motor power | 1.1 KW | |

| Speed adjustment method | ABB Variable Frequency Speed Control | |

| 4. DX-6000 Vacuum Shaping Stage | Platform Length | 6000 mm |

| Platform Material | 201 stainless steel | |

| Vacuum system | 5.5 KW × 2 units | |

| Cooling system | 2.2 KW water pump × 1 unit | |

| Drying system | 1.1 KW vortex blower × 1 unit | |

| 5. QY-300 integrated traction cutting machine | Traction section | |

| Traction method | Dual track traction, silicone rubber blocks | |

| Traction speed | 0.5 - 6 m/min | |

| Motor power | 1.5 KW × 2 units (ABB variable frequency speed control) | |

| Cutting part | ||

| Cutting method | Pneumatic clamping, alloy saw blade | |

| Cutting motor power | 2.2 KW | |

| Cutting mode | Automatic/Manual Fixed Length Cutting | |

| 6. XL-3000 unloading device | Device length | 3000 mm |

| Countertop material | Stainless steel |

B. Summary of Auxiliary Equipment Technical Parameters

| Equipment Name | Core parameters | Specifications and Instructions |

| SHR-Z300/600 High and Low Temperature Mixing Unit | Hot Mixing Volume | 300L (effective 210L), 55KW motor (ABB inverter) |

| Cold Mixed Volume | 600L (effective 420L), 11KW motor | |

| Mixed cycle | 8-12 minutes/pot | |

| LM-1000 Floor Sander | Maximum processing width | 1000 mm |

| Sanding frame motor power | The first sander has a power output of 22 kW, and the second sander has a power output of 11 kW. | |

| Sanding belt size | 1030 × 2200 mm | |

| BF350B-PUR-IV Coating Machine | Maximum processing width | 350 mm |

| Lamination speed | 0-50 m/min | |

| control system | PLC touch screen, PUR glue supply system |

Eaststar Electric Partners

We use globally renowned brands:

| Frequency converter | ABB |

| Temperature controller | OMRON/ Delta |

| Contactors and circuit breakers | Siemens/ Schneider |

Certificates

SPC (Stone Plastic Composite) flooring`s core characteristics are:

Superior stability: Almost unaffected by temperature and humidity, suitable for geothermal and humid environments.

100% Waterproof: The core layer is completely waterproof, making it an ideal choice for spaces such as kitchens and bathrooms.

Green and environmentally friendly: Free of formaldehyde, heavy metals and other harmful substances.

High durability: The wear-resistant surface layer makes the product scratch-resistant and has a long service life.

Easy installation: Most models use a snap-lock design, allowing for quick and easy installation directly on the existing floor.

Stone Plastic Flooring Extrusion Production Line Structure

A complete SPC flooring production line integrates a complex system of multiple precision modules to ensure the superior quality of the final product.

The complete production process is as follows:

About Eaststar

Qingdao Eaststar Plastic Machinery Co., Ltd. is a professional enterprise specializing in the research, development, manufacturing, and sales of high-performance plastic extrusion equipment. With over twenty years of technical expertise and rich project experience, we deeply understand the practical problems our customers encounter in production. Our goal is to provide global customers with technologically advanced, stable, and cost-effective complete production line solutions, along with comprehensive after-sales service.

Services we provide for SPC flooring projects

Customized solution design: We provide the most optimized equipment configuration solutions based on your product specifications and production capacity requirements.

Turnkey projects: Providing a full range of services from workshop planning, equipment installation and commissioning, operation training to process guidance.

Lifetime technical support: After equipment delivery, we provide ongoing technical consultation and process optimization support.

Comprehensive after-sales support: One-year equipment warranty, long-term supply of spare parts.

Frequently Asked Questions

Q1: What is an SPC flooring extrusion production line?

A1: The SPC flooring extrusion production line is the core equipment used for the large-scale production of stone-plastic composite (SPC) flooring. It uses a conical twin-screw extruder to plasticize and compact the stone powder/PVC mixture, form the flooring substrate through a die, and then produce high-quality SPC flooring core boards through cooling, shaping, and cutting processes.

Q2: How does SPC flooring compare to LVT or WPC?

A2: SPC flooring offers enhanced rigidity and stability over LVT and WPC due to its stone-plastic core, making it perfect for high-traffic environments.

Q3: Can the machine produce varying SPC flooring thicknesses?

A3: Yes, the machine supports SPC flooring thicknesses from 3 to 6 mm, customizable to meet diverse market requirements.

Q4: How long is the delivery time?

A4: Our standard delivery time is 35-40 working days after receiving the prepayment.