- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

PE Drainage Board Production Line

Qingdao Eaststar, leveraging its deep technical expertise in wide-width extrusion, has launched a high-performance PE drainage board production line. Designed specifically for building infrastructure, underground engineering, and landscaping projects, this line utilizes a 105/33 large-diameter single-screw extruder and precision two-roll molding technology to ensure uniform sheet texture and efficient drainage. With robust plastic sheet production line manufacturing processes and top-tier electrical components from Siemens and ABB, we help customers enhance their production competitiveness and ensure a stable supply of engineering materials.

Model:SJ 105/33

Send Inquiry

PE Drainage Board Production Line Overview

EASTSTAR's PE drainage board production line is a complete and efficient solution designed for the large-scale production of high-quality, high-density polyethylene (PE) drainage boards. This integrated production line automates the entire process from feeding and extrusion to molding and winding. At the heart of this production line is a robust 105/33 single-screw extruder paired with a precision coat hanger-style T-die, ensuring stable and consistent melt flow for uniform output. Furthermore, the line is equipped with an advanced twin-roll forming unit and a vacuum system, enabling precise production of drainage boards with a standard width of 1500mm and an adjustable thickness from 0.8mm to 1.2mm. Renowned for its reliability, precision, and high degree of automation, this production line is the preferred choice for applications in construction, civil engineering, and landscaping.

Complete Equipment List for PE Drainage Board Production Line

| No. | Equipment Name | Qty. | Key Notes |

| 1 | Feeding System | 1 set | Vacuum feeder with stainless steel hopper |

| 2 | 105/33 Single-Screw Extruder | 1 unit | Core extrusion unit, Output 250-280Kg/h |

| 3 | Screen Changer | 1 unit | Hydraulic, dual-position automatic |

| 4 | Metering Pump | 1 set | Precision melt pump for stable output |

| 5 | L=1650 T-Die | 1 unit | Coat-hanger design, Product width 1500mm |

| 6 | L=1700 Two-Roll Forming Unit | 1 set | Core forming unit, with vacuum system |

| 7 | Cooling Bracket & Edge Trimmer | 1 set | 6m length, includes scrap collection |

| 8 | Haul-Off Unit | 1 set | Rubber-coated rolls for stable traction |

| 9 | Cross-Cutter | 1 unit | Automatic length measurement & cutting |

| 10 | Winder | 1 unit | Friction winder, max. roll dia. 500mm |

| 11 | Electrical Control System | 1 set | Fully integrated automatic control |

Key Features of the PE Drainage Board Production Line

Highly Efficient and Stable Extrusion: The core 105/33 high L/D ratio single-screw extruder utilizes a nitrided 38CrMoAlA screw and barrel, offering superior hardness and abrasion resistance. Driven by a powerful 90kW motor, the line achieves high-volume plasticization of PE materials, with an output of up to 250-280 kg/hour.

Precise Output and Uniformity: This production line is equipped with a precision melt metering pump and a specially designed coat hanger-style T-die. The die flow channel is chrome-plated and mirror-polished to ensure uniform melt distribution and consistent sheet thickness. The forming rollers are precision ground and chrome-plated, resulting in an exceptionally smooth surface and ensuring a smooth and flat sheet surface.

Fully Automated and Reliable Control: Automation permeates the entire production process: automatic feeding, hydraulic screen changing, servo-controlled forming, and automatic length measurement/winding. The control system uses a Siemens S7 series PLC and ABB frequency converters, with key low-voltage components sourced from Schneider Electric and Siemens, ensuring reliable operation and precise control.

Robust and Durable: The twin-roll forming unit features solid steel side plates and is equipped with Japanese NSK bearings. The rollers are driven by a high-power servo system, featuring a robust structure and high pressure resistance, making them ideal for long-term continuous operation.

PE Drainage Board Production Line Core Component Technical Details

A. Overall Line Performance

Product Specifications: Width 1500mm; Thickness 0.8mm, 1.0mm, 1.2mm (Single Layer)

Extrusion Output: 250-280 kg/hour

Raw Material: PE granules (Melt Flow Rate: 0.9-2.0)

B. Core Component Technical Specifications

1. SJ105/33 Single Screw Extruder

| Model | 105/33 |

| Screw and Barrel | Jin Hailuo |

| Material | 38CrMoAIA |

| Nitriding Depth | 0.5-0.7mm |

| Screw Hardness | HV≥740 |

| Barrel Hardness | HV≥940 |

| Screw Diameter | 105mm |

| L/D Ratio | 33 |

| Barrel Heating Method | Ceramic Heating |

| Number of Heating Zones | 6 |

| Total Heating Power | 36Kw |

| Cooling Method | Fan Cooling |

| Power | 6 × 0.25kw |

| Driver | |

| Motor | Wango |

| Power | 90Kw |

| Speed Controller | ABB |

| Gearbox | Jiangyin Gearbox |

| Meshing Type | Helical Tooth Surface |

| Heat Treatment | Carburizing and Grinding |

| Connection Type | Direct Drive |

2. L=1700 Twin Roll Forming Unit

| Drainage board structure | 10/20/30mm (choose one), cylindrical, or custom-made according to sample. |

| Active roller vacuuming | with high-pressure vacuum pump. |

| Roller material | High-quality 45# steel. |

| Roller structure | Special multi-channel design. |

| Roller diameter | Φ450mm. |

| Effective roller width | 1700mm. |

| Coaxiality | ≤0.01mm. |

| Roller surface finish | Ra≤0.025um. |

| Roller surface hardness | HRC58-62. |

| Chrome plating thickness | 0.08mm. |

| Transmission gearbox | Felloca. |

| Transmission power | 2.9Kw. |

| Speed control | Huichuan servo. |

| Two-roller gap adjustment method | Electromechanical opening and closing, manual worm gear fine adjustment, with self-locking function, safety emergency stop switch, and synchronous control system. |

| Two-roller type | Vertical. |

| Two-roller wall panel | Solid steel plate. |

| Two-roller self-aligning roller bearings | NSK (Japan). |

| Rotary joint | Sino-foreign joint venture |

3. Electrical Control System

We insist on using globally renowned brands in key areas to ensure reliability:

| Operating panel | Siemens S7 series |

| PLC, temperature control module | Siemens S7 |

| Main motor speed controller | ABB |

| Metering pump speed controller | ABB |

| Molding machine controller | Huichuan servo |

| Contactors | Schneider or Siemens |

| Relays | ABB |

| Low-voltage circuit breaker | Schneider |

| Air switch | Siemens/Schneider |

| Buttons, switches, indicator lights | Schneider |

| Display meter | Autonics |

Certifications

Applications and Product Characteristics

This production line is specifically designed for the production of PE drainage boards and is widely used in:

Basic Drainage: For buildings, tunnels, and underground structures.

Landfill Sites and Landscaping: As a drainage layer in civil and environmental engineering.

Roof gardens and vertical greening: Provides essential drainage for horticultural applications.

Key characteristics of the produced PE drainage boards include:

High strength and durability: Withstands soil pressure and mechanical stress.

Excellent drainage capacity: Achieves efficient drainage through its carefully designed structure.

Corrosion resistance: Offers a long service life under various soil and moisture conditions.

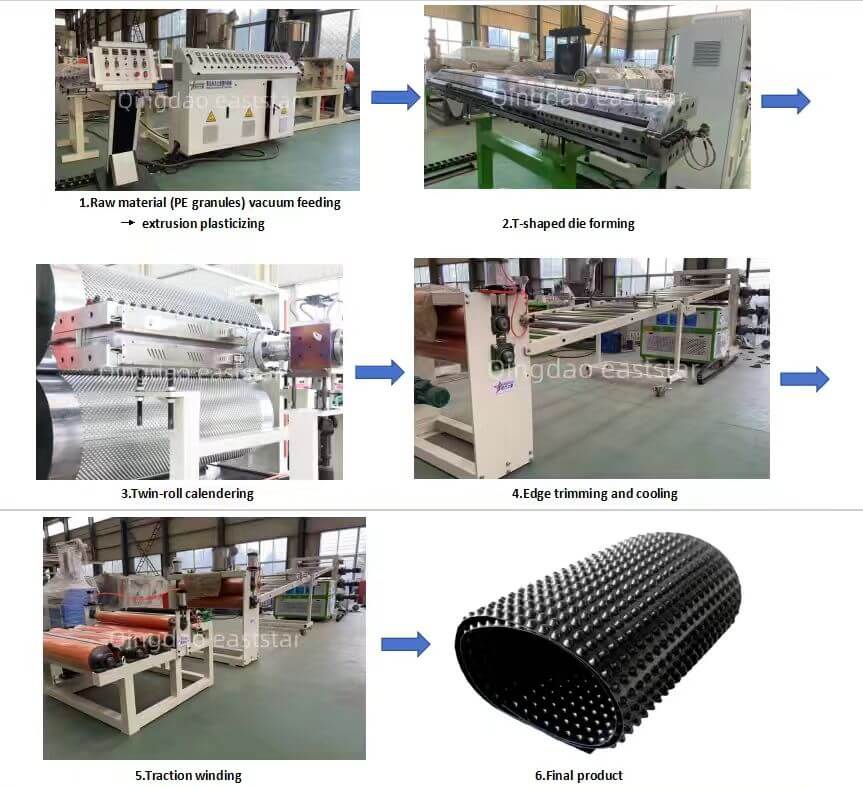

Complete Production Process:

About EASTSTAR

Qingdao Eaststar Plastic Machinery Co., Ltd.'s main products include: plastic sheet production equipment, plastic profile equipment, automobile interior and exterior decoration production equipment, smart agricultural cultivation equipment, new material extrusion equipment, and various plastic auxiliary processing equipment. The company's products are distributed worldwide and exported to Southeast Asia, the Middle East, South America, and other countries.

Services We Provide for PE Drainage Board Projects

1. The Seller shall provide the Buyer with installation drawings for the complete set of equipment; and, according to the Buyer's requirements, dispatch technical personnel to the Buyer's site to guide and assist in the installation, commissioning, and operator training of the equipment until the Buyer's operators can independently produce qualified products.

2. After installation, if trial operation conditions permit, the Seller shall provide on-site training for equipment operators as needed and provide the Buyer with comprehensive production process technical services.

3. Customized Solution Design: We provide optimized equipment configurations based on your specific product specifications and capacity requirements. 5. The equipment's operating direction and exterior paint color can be customized according to the buyer's requirements.

6. The supplier will meet the buyer's contract delivery time requirements.

7. Subsequent maintenance or replacement parts will only incur cost charges.

Frequently Asked Questions

Q: Are you a machinery factory or a trading company?

A: We have our own factory, which means we can strictly guarantee product quality and delivery time, and we don't charge middlemen.

Q: Do you provide equipment testing services?

A: Yes, we provide on-machine testing services. An additional testing fee will be charged based on testing costs (electricity, labor, etc.).

Q: What about the one-year warranty after-sales service?

A: Free replacement of parts within one year (excluding damage caused by human error). Maintenance or replacement of parts after one year will only incur cost charges. Lifetime technical support is provided.

Q: How can I effectively get a quote?

A: Please click the "Send Inquiry" button on the page or the message icon button on the right and select your preferred contact method. Leave a message describing the details of your final product (preferably with pictures and dimension drawings), production requirements, etc. We will reply to your inquiry within 12 hours.

Q: How can we visit your company and machines?

A: Our factory is located in Jiaozhou City, Qingdao, Shandong Province, China, with convenient transportation, 18 kilometers from Qingdao Jiaodong International Airport.

Q: What are the payment terms?

A: T/T

Contact EASTSTAR now for detailed technical specifications and a formal quotation for this high-performance PE drainage board production line!