- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

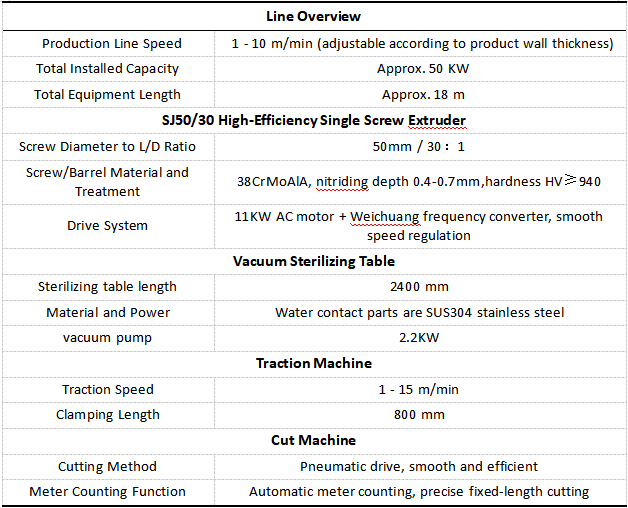

PC PS ABS lamp cover production line

Qingdao Eaststar, a professional manufacturer of PC PS ABS lamp cover production lines, proudly presents this high-performance PC/PS/ABS lamp cover production line. This line integrates high plasticization rate, fully automated control, and stable continuous production, specifically designed for producing high-precision, high-quality LED lamp diffusers. It utilizes high-quality 38CrMoAlA nitriding screws and barrels, along with imported brand electrical components, ensuring the equipment's durability. Contact us now for a customized quote and technical support!

Model: SJ 50/30

Send Inquiry

I. Core Advantages and Selling Points

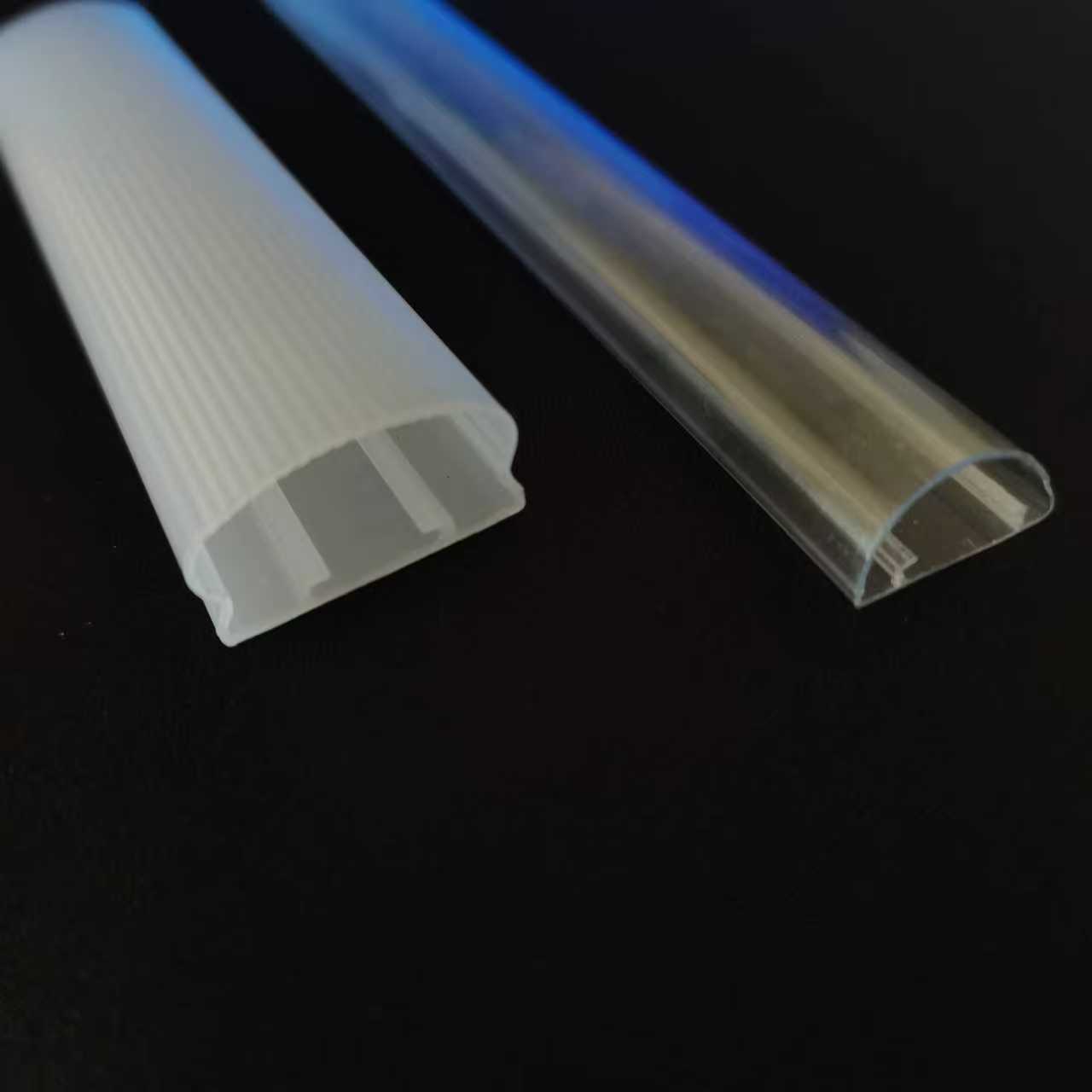

Superior Plasticization, First-Class Output: Employing our independently developed new high-plasticization screw and optimized slotted sleeve, it ensures uniform and consistent melt flow for engineering plastics such as PC, PS, and ABS, fundamentally guaranteeing the lamp cover's light transmittance and dimensional stability.

Rock-solid, Stable and Durable: The core hardened gear reducer delivers high torque and low noise; key electrical components are sourced from international brands such as Siemens and Omron, ensuring the entire line can handle 24/7 uninterrupted continuous production, minimizing the failure rate.

Intelligent automation, worry-free and labor-saving: From automatic vacuum feeding and drying to automatic meter counting and cutting, the entire line is integrated and controlled, greatly reducing reliance on operator skills and labor costs. One person can monitor the entire line.

Precise shaping, extremely high yield: The 2400mm long stainless steel vacuum shaping table, combined with a precision water temperature control system, can quickly and evenly remove heat, effectively controlling product cooling deformation and ensuring extremely high product smoothness and dimensional accuracy.

II. Technical Parameters and Professional Explanation

Equipment display

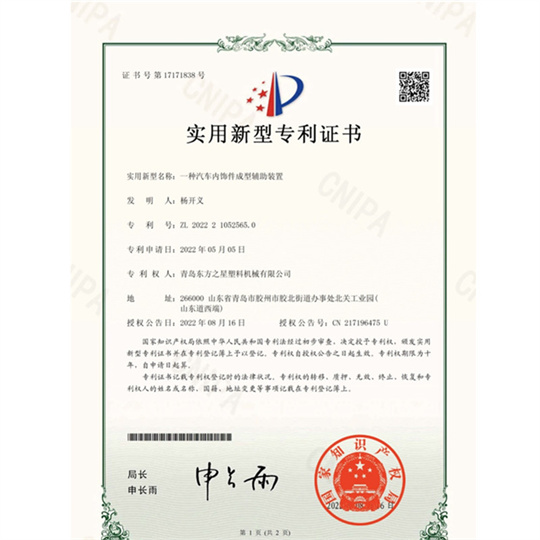

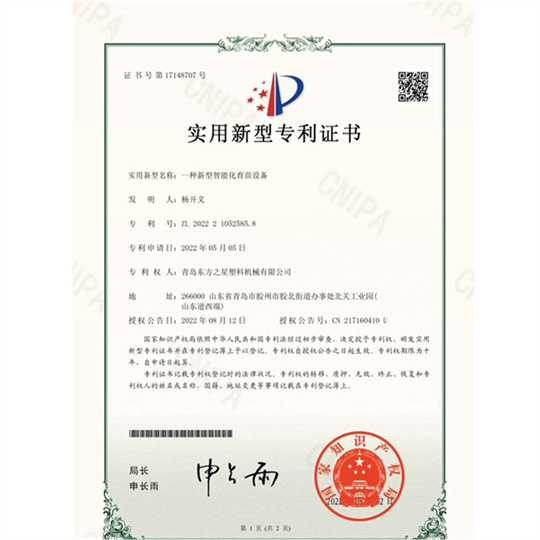

III. Authoritative Certifications and Brand Strength

Professional Foundation:Qingdao eaststar has been deeply involved in the plastic extrusion equipment field for over 11 years. We deeply understand every detail and challenge in lampshade manufacturing.

Material Commitment: Core components such as the screw and barrel are made of top-grade alloy steel and undergo strict nitriding treatment according to national standards. Brittleness is controlled within level 2, ensuring wear and corrosion resistance and significantly extending service life.

Brand Alliance: We insist on using well-known brands such as Siemens low-voltage electrical appliances, Omron intelligent temperature controllers, and Weichuang frequency converters in key parts, ensuring the long-term stability of your equipment operation from the source of the supply chain.

IV. Application Scenarios and Solutions

This PC PS ABS lamp cover production line is your powerful assistant in entering the high-quality lighting market:

Core Application: Professional production of various LED tube covers and diffusers, including T5, T8, and T10 tubes.

Material Compatibility: Perfectly compatible with engineering plastics such as PC (polycarbonate), PS (polystyrene), and ABS, meeting diverse needs from high light transmittance to high toughness.

Customized Services: You only need to provide drawings or samples, and our engineering team can tailor-make molds and optimize production line configurations for you, providing a one-stop solution from equipment to output.

V. Customer Testimonials and Service Process

Customer photos

Our service process is clear and transparent:

1.Requirement Communication: You provide your product requirements (drawings/samples/capacity).

2.Solution Quotation:We provide a detailed production line configuration and quotation.

3.Contract Signing: Both parties confirm the contract terms.

4.Delivery and Installation:After you pay the remaining balance, we ship the goods and send an engineer to your location for installation and commissioning guidance.

5.Training and After-Sales Service:We train your operators and provide lifetime technical support.

VI. Frequently Asked Questions (FAQ)

Q1: What are the payment methods?

A1: We support T/T wire transfer. Payment methods are flexible: 30% prepayment upon signing the contract, and the remaining 70% before equipment shipment.

Q2: What specific after-sales service is included? A2: We offer:

One-year free warranty on the entire machine (for parts damaged due to non-human factors).

Long-term supply of spare parts at cost price.

Lifetime free remote technical consultation service.

Support for third-party inspection, giving you peace of mind when purchasing.

Q3: How long is the delivery time?

A3: After receiving the prepayment, we will complete the production of the standard configuration equipment and prepare it for shipment within 30-45 working days.

VII. Clear After-Sales Guarantee

We solemnly promise:

Warranty Period: 12-month warranty on the entire machine.

After-Sales Response: 7x24-hour technical consultation support. For customers within 900 kilometers in China, we will dispatch service personnel within 2-5 days after receiving notification.

Extended Services: Long-term provision of production process technical guidance to help you quickly start production and improve efficiency.

Certificate

Contact Qingdao Eaststar sales engineers now to get a customized production line solution and the latest quotation! Let us use professional equipment and reliable service to help your business shine!