- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

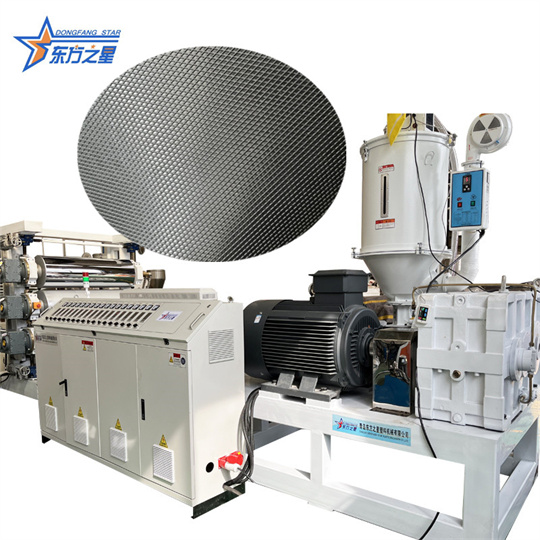

China High-efficiency plastic extrusion production line, Manufacturers, Suppliers, Factory

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We're on the lookout forward for your stop by for joint growth for High-efficiency plastic extrusion production line,,PC lamp cover extruder,,ABS lamp cover production line price,,Automatic lamp cover production equipment,,Customized lamp cover production line,, If you're on the lookout forever Excellent at a superior selling price and timely delivery. Do speak to us.

High-efficiency plastic extrusion production line,, now we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality items with the very competitive price.

Hot Products

PE Sheet Extrusion Line

Eaststar stands as a distinguished supplier and manufacturer of PE Sheet Extrusion Lines, renowned for their commitment to customization. With a focus on customization, they ensure that each extrusion line is optimized to meet the unique needs of their clientele, setting a standard of excellence in the field.PP Sheet Printing Machine

Eaststar, a distinguished manufacturer in the industry, operates a cutting-edge factory dedicated to the production of PP Sheet Printing Machines. Renowned for their commitment to excellence, Eaststar designs and manufactures machinery that sets the standard for precision and quality in PP sheet printing.Plastic Seedling Tray Machinery

Eaststar is a leading manufacturer in China specializing in the production of advanced Plastic Seedling Tray Machinery. With a state-of-the-art factory and a commitment to innovation, Eaststar has established itself as a reliable supplier in the industry. Their machinery is designed to meet the specific demands of producing high-quality seedling trays, catering to the needs of nurseries and agricultural enterprises.PS Blister Packaging Sheet Production Line

Eaststar is a trusted manufacturer from China that specializes in the production of PS blister packaging sheet production lines. With years of experience in the industry, Dongfang Star has gained a reputation for delivering high-quality and reliable production lines for producing superior PS blister packaging sheets. Their products are widely used in the packaging industry and are known for their efficiency, durability, and cost-effectiveness. If you're in need of a dependable and efficient PS blister packaging sheet production line, Dongfang Star is an excellent choice.PA POM Sheet Extruder Machine

The PA POM Sheet Extruder Machine of: single-screw extruder, three-roller calender, cooling bracket with automatic trimming device, rubber roller traction machine, and winding machine. Products of different specifications can be produced according to different requirements of customers. Sheets with different surfaces can be produced with smooth, orange peel, and matte surfaces.Pvc Anti-slip Mat Equipment Soft Sheet Machine

Pvc Anti-slip Mat Equipment Soft Sheet Machine: The equipment mainly consists of a single-screw extruder, a three-roller calender, a 6-meter cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device.