- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

PVC Steel Wire Reinforced Hose Extrusion Production Line

EASTSTAR is a professional manufacturer of plastic extrusion production lines. Our high-performance PVC steel wire reinforced hose extrusion production line is designed specifically for producing high-strength, pressure-resistant steel wire reinforced hoses. The production line integrates an SJ-90 high-torque extruder and a precision steel wire winding and coating system, ensuring a perfect composite of steel wire and PVC, producing hoses that are pressure-resistant, anti-flattening, and have a long service life. Core components utilize 38CrMoAlA nitrided steel and electrical components from international brands such as ABB and Siemens, ensuring long-term equipment stability. Contact EASTSTAR now for customized solutions and quotes!

Model:SJ-90

Send Inquiry

I. Core Advantages and Selling Points

Powerful Plasticization, Tight Coating: The SJ-90 extruder features a 28:1 L/D ratio optimized screw, ensuring uniform PVC plasticization; combined with a precision coating die, it achieves 360° perfect coating of the steel wire without any dead angles, eliminating wire breakage and air leakage.

Robust and Durable, Continuously Stable: The screw and barrel are made of top-grade 38CrMoAlA nitrided steel, offering high hardness and excellent wear resistance; the hardened gear reducer uses 20CrNi2MoAR material and undergoes carburizing and grinding processes, transmitting high torque and operating with low noise, suitable for continuous production in all weather conditions.

Automated Integration, Superior Efficiency: From steel wire winding, PVC extrusion coating, water cooling, traction to dual-station automatic winding, the entire line operates automatically, significantly improving production efficiency and reducing labor costs.

Brand Configuration, Reliable Guarantee: Key electrical components utilize ABB frequency converters, Siemens contactors, and Omron temperature controllers, ensuring precise equipment control and reliable operation from the source.

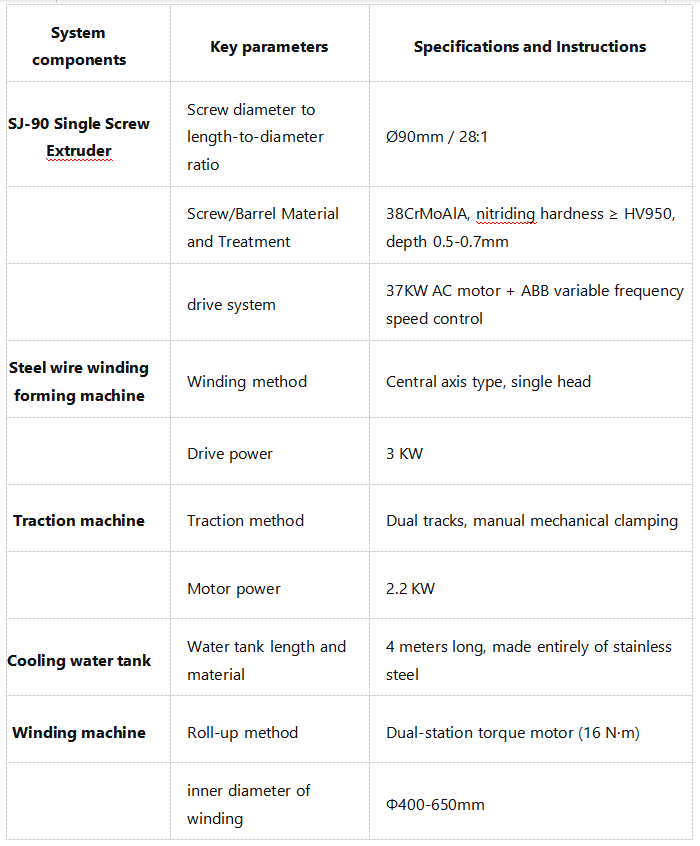

II. Detailed Technical Parameters

III. Authoritative Certification and Quality Assurance

Professional Manufacturing: With over ten years of experience in R&D and manufacturing of steel wire reinforced pipe equipment, we have a deep understanding of the core processes of pressure-resistant pipelines.

Material Commitment: All core transmission gears are made of 20CrNi2MoAR vacuum degassing refined gear steel and undergo precision heat treatment such as carburizing and gear grinding to ensure equipment lifespan.

Stringent Standards: All equipment undergoes rigorous no-load and load tests before leaving the factory to ensure that all indicators meet design requirements.

Certificate

IV. Application Scenarios and Solutions

This PVC Steel Wire Reinforced Hose Extrusion Production Line is the ideal choice for producing high-performance steel wire reinforced hoses:

Core Applications: Widely used in the manufacture of industrial suction and drainage hoses, agricultural irrigation pipes, mining ventilation pipes, fire hose reinforcement layers, and other types of steel wire reinforced PVC hoses.

Product Range: Can produce steel wire hoses in various specifications such as Φ36mm, Φ41mm, and Φ51mm to meet different pressure resistance requirements.

Customized Services: Can provide a complete solution from equipment configuration and mold development to production processes according to your specific needs.

V. Customer Testimonials and Service Process

Customer Photos

--“EASTSTAR’s steel wire hose production line operates very stably, the burst pressure of the produced hoses fully meets the standards, and the after-sales service is also very timely. It is our first choice for capacity expansion.” — A large hose manufacturer in Shandong--

》 》 》Our service process is clear and transparent :

Requirement Communication: You provide product specifications, production capacity, and special requirements.

Solution Quotation: We provide a detailed production line configuration and quotation plan. Contract Signing: Both parties confirm the contract terms.

Production and Acceptance: We arrange production and invite you to our factory for load testing and acceptance.

Delivery and Installation: After payment of the remaining balance, we will ship the goods and send an engineer to provide on-site guidance for installation and commissioning.

Training and After-Sales Service: We will train your operators and provide lifetime technical support.

VI. Frequently Asked Questions (FAQ)

Q1: What are the payment methods?

A1: We support T/T wire transfer. The payment method is: 50% prepayment upon signing the contract, and the remaining 50% before the equipment leaves the factory.

Q2: What does after-sales service specifically include?

A2: We provide:

a. One-year free warranty on the entire machine (for core components such as the screw, barrel, gearbox, and motor, which are not damaged by human error).

b. Long-term supply of spare parts at cost price.

c. Lifetime free remote technical consultation service.

Q3: How long is the delivery time?

A3: Upon receiving the prepayment, we will complete the production of the equipment and prepare it for shipment within 30-45 working days.

VII. Clear After-Sales Guarantee

Warranty Period: 12-month warranty on the entire machine.

After-Sales Response: We provide technical consultation support and respond quickly to your questions.

Extended Services: We provide long-term production process technical guidance and spare parts supply to ensure your continuous and smooth production.

Contact an EASTSTAR sales engineer now to learn about the detailed configuration and latest preferential prices of this high-performance steel wire reinforced hose production line! Let us use professional equipment to safeguard the strength of your products!