- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Steel Wire Hose Production Equipment, Manufacturers, Suppliers, Factory

"Based on domestic market and expand abroad business" is our improvement strategy for Steel Wire Hose Production Equipment,,PVC Steel Wire Reinforced Hose Production Line,,Steel Wire Reinforced Hose Extrusion Equipment,,SJ-90 Single Screw Extruder,,PVC Steel Wire Hose Production Line Price,, Now we have established steady and long business relationships with customers from North America, Western Europe, Africa, South America, more than 60 countries and regions.

Steel Wire Hose Production Equipment,, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

Hot Products

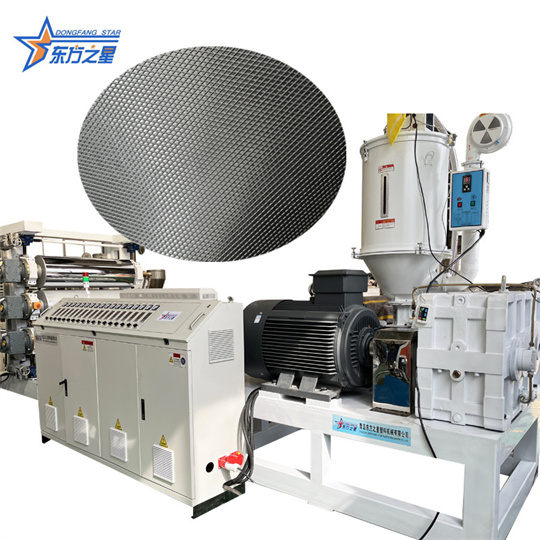

Car PVC Flooring Extrusion Machine

Eaststar, a reputable manufacturer in the industry, specializes in producing Car PVC Flooring Extrusion Machines. What sets Eaststar apart is their commitment to providing high-quality machinery at a competitive price point. The Car PVC Flooring Extrusion Machines manufactured by Eaststar are designed to meet the precise requirements of automotive PVC flooring production, ensuring efficiency and precision in every extrusion.Planting Trays Seedling Making Machine

Eaststar, a distinguished manufacturer based in China, specializes in the production of high-quality Planting Trays Seedling Making Machines. Collaborating with reputable suppliers, Eaststar sources top-notch components, guaranteeing the exceptional performance and reliability of their machinery. Eaststar's Planting Trays Seedling Making Machines are trusted by suppliers worldwide for their advanced technology and reliable production capabilities.PVC Sealing Strip Equipment

PVC sealing strip equipment has been used in the production of automobiles, doors and windows, cabinets, refrigerators, containers and other industries. According to the requirements of different industries, we have developed automobile sealing strips, mechanical sealing strips, door and window sealing strips and other products.PP Coated Pipe Equipment

PP coated pipe equipment PP coated pipe equipment is mainly used for coating the surface of various metal pipes with a layer of plastic. Stainless steel pipe diameter: 1-200mm can be customized according to customer requirements; Surface coating materials for PP coated pipe equipment: PE, PP, PVC, PA, etc; Coating speed: 0.5-50 meters per minute. Production process of PP coated pipe equipment: Stainless steel pipes on the wire rack or material rack are first preheated by a heating device, then wrapped in plastic by the main machine coating mold, cooled by a circulating water tank, pulled by a traction machine to the wire storage rack, and then automatically cut to a fixed length. Due to different processing techniques for various profiles, the required equipment configuration and equipment are also different.Soft Pvc Sheet Single Screw Extruder Making Machine

Soft Pvc Sheet Single Screw Extruder Making Machine : The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.PVC Sheet Extrusion

As the professional manufacture, EASTSTAR would like to provide you PVC Sheet Extrusion. And EASTSTAR will offer you the best after-sale service and timely delivery.