- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China PVC Steel Wire Hose Production Line Price, Manufacturers, Suppliers, Factory

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for PVC Steel Wire Hose Production Line Price,,PVC Steel Wire Reinforced Hose Production Line,,Steel Wire Reinforced Hose Extrusion Equipment,,SJ-90 Single Screw Extruder,,Steel Wire Hose Production Equipment,, For high-quality gas welding & cutting equipment supplied on time and at the right value, you can count on organization name.

PVC Steel Wire Hose Production Line Price,, We pay high attention to customer service, and cherish every customer. Now we have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

Hot Products

Seedling Tray Seeder Making Machine

Based in China, Eaststar is a prominent supplier of Seedling Tray Seeder Making Machines. These machines are meticulously crafted to meet the demands of nurseries and agricultural enterprises. Eaststar's state-of-the-art factory employs cutting-edge technology to manufacture high-quality equipment. Collaborating with trusted suppliers, Eaststar ensures the use of top-notch components, ensuring the efficiency and durability of their machinery. With a reputation for advanced technology and reliable production capabilities, Eaststar is a preferred choice for suppliers worldwide in need of top-grade Seedling Tray Seeder Making Machines.Root Control Making Machine PS Root Controller Forming Machine

Root Control Making Machine PS Root Controller Forming Machine root controldevice is mainly in accordance with the working principle of hot pressing equipment design. Root control equipment can also produce water spraying sheets 1. Root Control Making Machine is mainly in accordance with the working principle of hot pressing equipment design, process is: sheet —— feeding —— heating —— pressing —— pressure —— molding —— cutting steps, appearance neat and practical, plate processing all processing center, ensure the accuracy of all hole size, column and pin appearance are hard chromium quenching treatment, ensure the sliding and wear resistance, machine system edited into manual and automatic two parts, in manual case all action can be single operation. 2: The feed motor is driven by a servo motor with a power of 2 kW. 3: feeding reducer motor 0.55KW and 1:10 special reducer, to ensure the stability of feeding speed! 4: Ceramic heating block: new ceramic heating block, heating fast and low power consumption, the temperature can be adjusted freely, according to the thickness of different materials. 5: Other mechanical parts are produced and processed by our company. Automatic control system adopts: Delta PLC control, 6: The machine adopts hydraulic balanced distribution design, the overall balance is better, to solve the situation of the high and low in the production to prolong the use time of the mold.ABS/PC Co-extruded Lamp Tube Cover Equipment

Defects of The PP/PC lamp case production line : 1.ABS/PC Co-extruded Lamp Tube Cover Equipment suitable for the collision of rigid pipes and special-shaped materials; the specific configuration depends on different origins Product design plan! 2. The PP/PC lamp case production line Applicable raw materials: PC, PMMA, ABS, rigid PVC, PP, PE and other pellets 3. The PP/PC lamp case production line Applicable pipe diameter range: round pipes, semicircles, and special-shaped products within OD120mm. 4. The PP/PC lamp case production line Suitable for brazing and two-color through co-extrusion extruder and mold. 5. The PP/PC lamp case production line Different products can adopt water-cooling, cold-top, air-cooling and other processesSoft Pvc Sheet Single Screw Extruder Making Machine

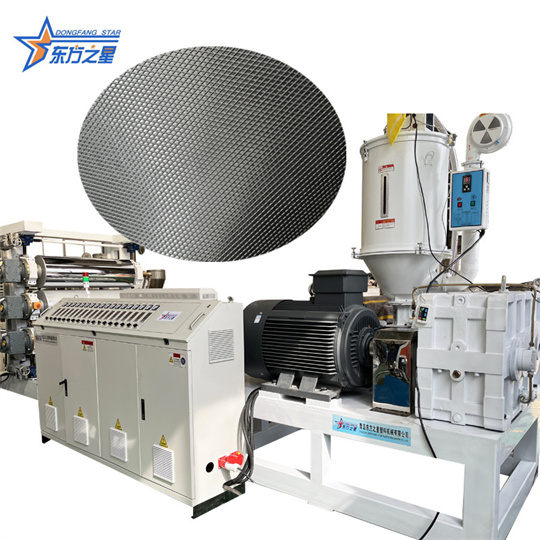

Soft Pvc Sheet Single Screw Extruder Making Machine : The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.Soft PVC Anti-skid Plate Extruder Equipment

Soft PVC anti-skid plate extruder equipment: The equipment mainly consists of a single-screw extruder, a three-roller calender, a 6-meter cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device.PVC Steel Wire Reinforced Hose Extrusion Production Line

EASTSTAR is a professional manufacturer of plastic extrusion production lines. Our high-performance PVC steel wire reinforced hose extrusion production line is designed specifically for producing high-strength, pressure-resistant steel wire reinforced hoses. The production line integrates an SJ-90 high-torque extruder and a precision steel wire winding and coating system, ensuring a perfect composite of steel wire and PVC, producing hoses that are pressure-resistant, anti-flattening, and have a long service life. Core components utilize 38CrMoAlA nitrided steel and electrical components from international brands such as ABB and Siemens, ensuring long-term equipment stability. Contact EASTSTAR now for customized solutions and quotes!