- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

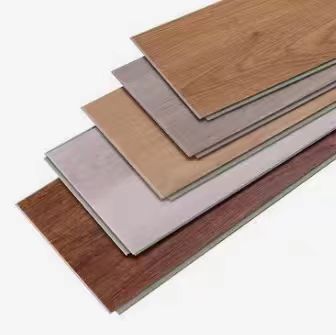

PVC/PE WPC Flooring Equipment

This PVC/PE WPC Flooring Equipment is designed for high-output manufacturing of eco-friendly WPC decks, tiles, and profiles. As a professional WPC flooring machinery supplier, we provide a complete automatic WPC production line from raw material to finished boards, ensuring superior product quality and low operational cost for your business.

Model:Single screw extruder SJ90/33

Send Inquiry

Looking to buy reliable PVC/PE WPC Flooring Equipment?Our WPC flooring production line is your top choice for building a profitable business in the sustainable building materials market. This automatic Wood Plastic Composite flooring machinery integrates advanced technology for high-efficiency manufacturing of various decking, tiles, and profiles.

The core of ourWPC flooring machinery includes a high-torque twin-screw extruder, precision calibration vacuum cooling table, and automatic cutting & stacking system. This setup guarantees stable operation, consistent product density, and a perfectly smooth surface finish, which are critical for high-quality PVC/PE Wood Plastic Composite flooring. The production line is designed for ease of operation, significantly reducing labor costs and manual intervention. Whether you are starting a new project or upgrading your existing capacity, our equipment delivers unmatched efficiency and output.

We are not just a seller but a long-term partner.We provide comprehensive services including formula support, custom mold design, installation guidance, and operator training. Our technical team ensures a smooth start-up for your WPC flooring production line. Invest in our machinery to produce premium-grade products that win more orders and maximize your return on investment. Contact us today for a free quote and solution consultation!

|

Equipment List |

||

|

Equipment Name |

Specification Model |

Quantity |

|

Automatic screw feeder |

LX-300 |

1 |

|

Single screw extruder |

SJ90/33 |

1 |

|

Forming platform |

DX-6000 |

1 |

|

Embossing machine |

|

1 |

|

Tractor |

|

1 |

|

Cutting machine |

|

1 |

|

Unloading device |

XL-3000 |

1 |

Important Notes

· Site Requirements: Confirm that your factory area, floor height, and power capacity (voltage/wattage) meet the equipment installation requirements.

· Raw Material Preparation: Please clarify the type of raw material you plan to use (PVC or PE-based), wood flour fineness, and formulation ratio so that we can provide the most suitable machine configuration.

· Mold Selection: The mold determines the cross-sectional shape and pattern of the final product. Please confirm in advance the flooring style you desire (hollow/solid, surface texture) and customize the corresponding mold.

· Capacity Matching: Select a machine model with appropriate capacity based on your market sales plan to avoid wasted investment or insufficient production capacity.

· After-sales Communication: Ensure a clear understanding of the supplier's after-sales service offerings, such as installation and commissioning, online guidance, engineer dispatch, warranty period, and spare parts supply.