- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

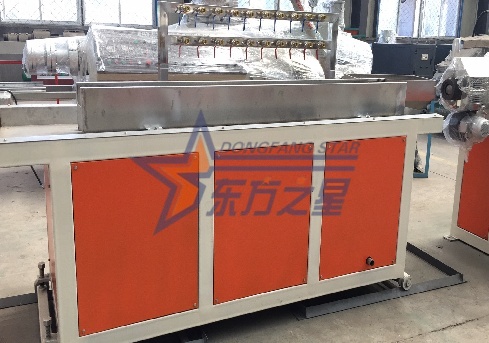

PP/PE/PVC/ABS Plastic Welding Rod Extrusion Line

The SJ-50 dual-line plastic welding electrode extruder offers a highly cost-effective solution for producing PVC, PP, PE, and ABS welding electrodes. Its compact, one-to-two design doubles output with minimal space and cost increases. Utilizing a material-specific screw and quick-change die, the machine ensures consistent electrode diameter and quality across a wide range of industrial welding and sealing applications, making it ideal for startups and expanding manufacturers.

Model:SJ 50/28

Send Inquiry

SJ-50 Dual-Line Plastic Welding Rod Extrusion Machine for PP, PE, PVC, ABS

✅ High-efficiency dual-line production: One-to-two design, one-time investment, double the output, extremely high cost-effectiveness.

✅ Multi-material compatibility: Professionally optimized screw and mold, perfectly adapted to the production of various plastic welding rods such as PP, PE, PVC, and ABS.

✅ Compact footprint: The entire line is only about 10 meters long, greatly saving factory space.

Technical Parameters and Configuration

Core Parameter Table |

|

| Item | Specifications |

| Applicable Raw Materials | PP, PE, PVC, ABS Granules |

| Standard Output per Line | 20 - 40 kg/h |

| Product Diameter Range | 3 - 5 mm (Customizable according to drawings or samples) |

| Extruder Model | SJ-50 (Dual-unit configuration) |

| Screw Diameter | 50 mm |

| L/D Ratio (L/D) | 28:1 |

| Single Main Motor Power | 15 kW |

| Heating Power | 9 kW |

| Cooling Method | Air cooling + water tank spray cooling |

| Total Installed Power | ≈ 30 kW (Dual-unit) |

| Production Line Dimensions (LWH) | ≈ 10m × 1.5m × 2.5m |

Core Component Brand |

|

| Inverter System | Shenzhen Weichuang (Veichi) |

| Electrical Components | CHINT |

| Gear Reducer | Jiangyin/Changzhou Brand |

| Screw and Barrel | 38CrMoALA Nitrogenated Steel |

In-Depth Technological Advantages

-

One-to-Two Design, Doubling ROI

A one-to-two extrusion production line doubles capacity with only a slight increase in cost and space.

-

Dedicated Screw and Modular Die Design Ensures Stable and Uniform Output

The screw is made of 38CrMoALA nitrided steel, wear-resistant and corrosion-resistant, optimized for the processing characteristics of PVC and polyolefins (PP/PE). The modular die head design allows for rapid production of welding rods of different diameters (3-5mm) by changing the die, offering flexible adjustments and minimizing waste.

-

Precise Temperature Control and Cooling Throughout the Process Improves Product Physical Properties

Partial heating of the barrel combined with an intelligent temperature controller ensures uniform plasticization. Equipped with a 2.4-meter stainless steel cooling water tank and spray system, it provides rapid and uniform cooling and shaping, effectively reducing internal stress in the welding rods, resulting in more stable and robust performance in subsequent welding applications.

Application Scenarios and Materials

-

Plastic Product Welding (Chemical Storage Tanks, Pipelines, Sheets)

-

Automotive Plastic Parts Repair

-

Waterproofing Project Sealing

-

DIY and Industrial Repair

This production line, with optimized processes, can efficiently process various thermoplastics such as PVC (Polyvinyl Chloride), PP (Polypropylene), PE (Polyethylene), and ABS (Acrylonitrile Butadiene Styrene), producing specialized welding electrodes for corresponding materials.

Our Quality and Service Commitment

Warranty Policy: 12-month quality guarantee from the date of delivery, free replacement of core components (excluding damage caused by human error).

Technical Support: Lifetime technical consultation provided. Engineers will be dispatched to guide installation, commissioning, and operation training (travel expenses borne by the customer).

Delivery Cycle: Shipment within 45-50 working days after order confirmation (FOB Qingdao).

Payment Method: T/T.

Frequently Asked Questions (FAQ)

1. Are you a factory or a trading company?

We are a manufacturer with our own factory, enabling us to strictly control product quality, cost, and delivery time, without any intermediaries.

2. Can you customize according to our special requirements?

Yes. We provide optimized configurations based on your product specifications and production capacity needs. The equipment's operating direction and exterior color can be customized, with design solutions provided by experienced mechanical engineers.

3. Do you provide trial operation services?

Yes, we provide factory trial operation services. A trial operation fee will be charged based on material, water, electricity, and labor costs.

4. How do you guarantee the equipment will operate well in your overseas factory?

If assistance is needed, we will send engineers to your factory for installation, commissioning, and personnel training, which typically takes 7-8 working days (excluding travel). Overseas clients are responsible for the engineer's round-trip airfare, local wages, accommodation, and safety.

5. What about after-warranty service?

After the warranty period, we provide lifetime technical support. Repairs or replacement parts will only incur cost charges.

6. How can I get an accurate quote?

Please click the "Send Inquiry" button on the page and provide as many details as possible about the final product (pictures, drawings), raw materials, and production capacity requirements. We will provide you with a detailed solution and quote within 12 hours.