- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China PP welding rod machine price, Manufacturers, Suppliers, Factory

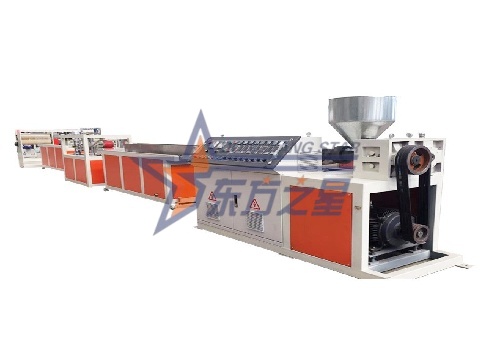

Our rewards are lessen selling prices,dynamic sales team,specialized QC,solid factories,high quality services for PP welding rod machine price,,plastic welding rod making machine,,PVC welding rod extrusion line,,small plastic rod production line,,automatic welding rod winding machine, "Making the Merchandise of Significant Quality" could be the eternal goal of our firm. We make unremitting endeavours to know the aim of "We Will Always Keep in Pace using the Time".

PP welding rod machine price,, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, be sure to click the button to acquire additional nformation.

Hot Products

PVC Transparent Door Curtain Production Line

Eaststar is a renowned manufacturer and factory based in China that offers high-quality PVC transparent door curtain production line. These machines are designed to produce PVC car curtains of different sizes and thicknesses, and they come equipped with advanced components such as a single-screw extruder, hydraulic automatic screen changer, and adjustable T-shaped flexible die. These components work together to ensure precision and efficiency in the production process, resulting in excellent PVC car curtains.PE Aluminum-Plastic Composite Panel Production Line

PE Aluminum-Plastic Composite Panel Production Line (also known as aluminum-plastic panel), as a new building material, and has been quickly favored by people for its economy, the diversity of optional colors, convenient construction methods, excellent processing performance, excellent fire resistance and noble quality. The unique properties of aluminum-plastic composite board determine its wide range of uses: it can be used for building exterior walls, curtain wall panels, renovation of old buildings, indoor wall and ceiling decoration, advertising signs, display stands, purification and dust prevention projects. It belongs to a new type of building material. The products produced by the equipment are mainly suitable for the inner and outer wall PE composite board, the thickness of the product is from 1-6mm, the width of 1200-1500mm two models, the thickness of the aluminum foil is from 0.03-0.5mm, and the bonding process of polymer film or glue can be selected. The equipment has the advantages of one molding, stable extrusion, firm compound, good flatness and so on.PVC Transparent Soft Door Curtains Machine

PVC Transparent Soft Door Curtains Machine Qingdao EAST STAR Plastic Machinery Co., Ltd. is mainly engaged in plastic sheet equipment. Our company's PVC soft door curtain equipment mainly consists of five parts: super mirror roller part, motor drive system, gap adjustment system, electrical control system, and frame. composition. Our company's PVC soft door curtain equipment can produce PVC transparent soft door curtains with a width of 200-400 mm and a thickness of 0.5-5 mm. This PVC soft door curtain equipment can produce three types of soft door curtains, including glossy, matte and striped, in one machine. It not only achieves multiple uses in one machine and is easy to operate, but also helps customers greatly save costs.Tree Root Control Equipment

Tree Root Control Equipment is mainly in accordance with the working principle of hot pressing equipment design. Root control equipment can also produce water spraying sheets 1. PET Root Plant Root Protection Equipment is mainly in accordance with the working principle of hot pressing equipment design, process is: sheet —— feeding —— heating —— pressing —— pressure —— molding —— cutting steps, appearance neat and practical, plate processing all processing center, ensure the accuracy of all hole size, column and pin appearance are hard chromium quenching treatment, ensure the sliding and wear resistance, machine system edited into manual and automatic two parts, in manual case all action can be single operation. 2: The feed motor is driven by a servo motor with a power of 2 kW. 3: feeding reducer motor 0.55KW and 1:10 special reducer, to ensure the stability of feeding speed! 4: Ceramic heating block: new ceramic heating block, heating fast and low power consumption, the temperature can be adjusted freely, according to the thickness of different materials. 5: Other mechanical parts are produced and processed by our company. Automatic control system adopts: Delta PLC control, 6: The machine adopts hydraulic balanced distribution design, the overall balance is better, to solve the situation of the high and low in the production to prolong the use time of the mold.PE Bag Edge Strip Extrusion Machine

PE Bag Edge Strip Extrusion Machine includes single screw compressor - machine head mold - vacuum shaping warehouse - traction tractor - winding machine or cutting machine 1. The main machine adopts hard tooth surface stop machine transmission, the screw barrel is made of high-strength quenched alloy steel (38CrMoALA) or high-strength quenched alloy steel (9Cr18MoV), and the main machine drive adopts AC variable frequency controller, no oil stains, low noise; temperature control The device adopts an intelligent temperature control meter, and the temperature control accuracy reaches ±1℃; 2. The main body of the stainless steel cooling pool is made of imported SUS304 material; the water tank frame adopts a threaded lift device, which can be adjusted in three dimensions up, down, left and right, making the operation very convenient; it is also equipped with a stainless steel water storage tank, so that the cooling water can be recycled without splashing on the ground; 3. The traction machine has variable frequency controller and the traction speed is steplessly adjustable. 4. The winding machine adopts frequency converter to adjust the speed to achieve the ideal production speed.TPU/PE/PP/PS-300 Wide Sheet Extrusion Line

The TPU/PE/PP/PS-300 Wide Sheet Extrusion Line is designed for processing pellets or crushed mixtures of TPU, PE, PP, and PS. With a production capacity of **60-100 kg/h**, the line includes components from leading brands like Siemens and Omron. It features a 0.8-3mm sheet die, three-roll calender, and winding machine, ensuring high-quality output. The equipment meets stringent quality standards and includes comprehensive technical documentation for ease of operation and maintenance.