- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

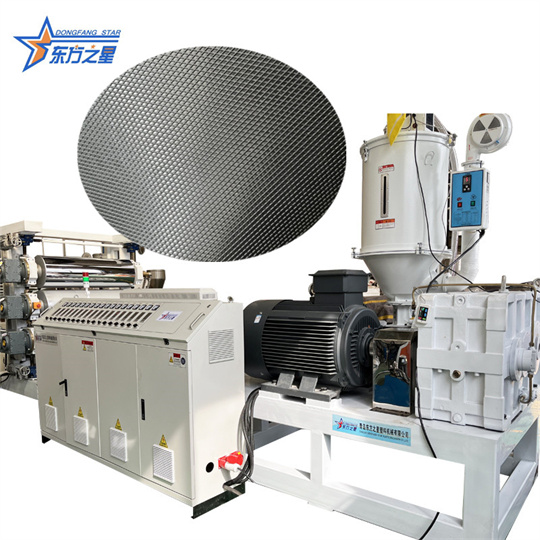

China Soft Pvc Turble Back Board Equipment Manufacturers, Suppliers, Factory

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Soft Pvc Turble Back Board Equipment,pvc sheet extruder machine, Let's cooperate hand in hand to jointly make a beautiful future. We sincerely welcome you to visit our company or contact us for cooperation!

Soft Pvc Turble Back Board Equipment, We have been persisting in the business essence "Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying merchandise and service. " Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.

Hot Products

PP Sheet Extrusion Line

Eaststar stands out as a prominent supplier and manufacturer in the field of PP Sheet Extrusion Lines. Specializing in customization, they offer top-tier machinery tailored to specific production needs. With Eaststar expertise, you can expect precision and efficiency in the extrusion process, resulting in high-quality PP sheets. Whether for packaging, industrial applications, or any other purpose, their extrusion lines are crafted to deliver outstanding performance.PE Root Controller Machine

Eaststar, a reputable company based in China, specializes in the production of high-quality PE Root Controller Machines.Collaborating with trusted suppliers, Eaststar sources top-notch components, guaranteeing the exceptional performance and reliability of their machinery. Eaststar's PE Root Controller Machines are trusted by suppliers worldwide for their advanced technology and reliable production capabilities.Plastic Root Prune Flower Pots Making Machine

Eaststar is a renowned supplier of durable Plastic Root Prune Flower Pots Making Machine. Built to last, Eaststar's machines ensure a seamless and reliable production process, making them a valuable asset for nurseries and gardening businesses. With Eaststar as your supplier, you can trust in the longevity and performance of their Plastic Root Prune Flower Pot Making Machines, enabling you to meet your production needs with confidence and ease.Geocell Production Line

Experience the pinnacle of quality with our Geocell Production Line, proudly manufactured in China. Geocells, known for their exceptional strength and durability, find diverse applications in infrastructure and environmental projects. With our high-quality production line, you can trust that your geocells will meet the rigorous demands of any project. Elevate your construction endeavors with the reliability and excellence of our Geocell Production Line.PVC Wall Panel Production Line

PVC wall panel production line consists of: ① Cone double main machine ② Glue extruder ③ Vacuum shaping table ④ Traction machine ⑤ Cutting machine ⑥ Material receiving rack The PVC wall panel production line adopts intelligent control, high degree of automation, stable operation, easy operation, and high production efficiency. In addition, our company has always adhered to the customer-oriented approach and always implemented the "turnkey" solution, providing customers with door-to-door installation, commissioning, production, and training and Raw material formula ensures that customers can produce independently and stably.Disposable Seedling Cup Plug Equipment

Disposable Seedling Cup Plug Equipment technical parameter Specification width of used sheet: 300~320mm, thickness: 0.8~2mm. Forming area (maximum): 400*600 mm, working efficiency of 15~20 times / minute. Power used: three-phase four-wire 380 volts, maximum power 25KW Hydraulic pressure: 100T External size (mm) length, width and height) 3600mm*980mm*1500mm