- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

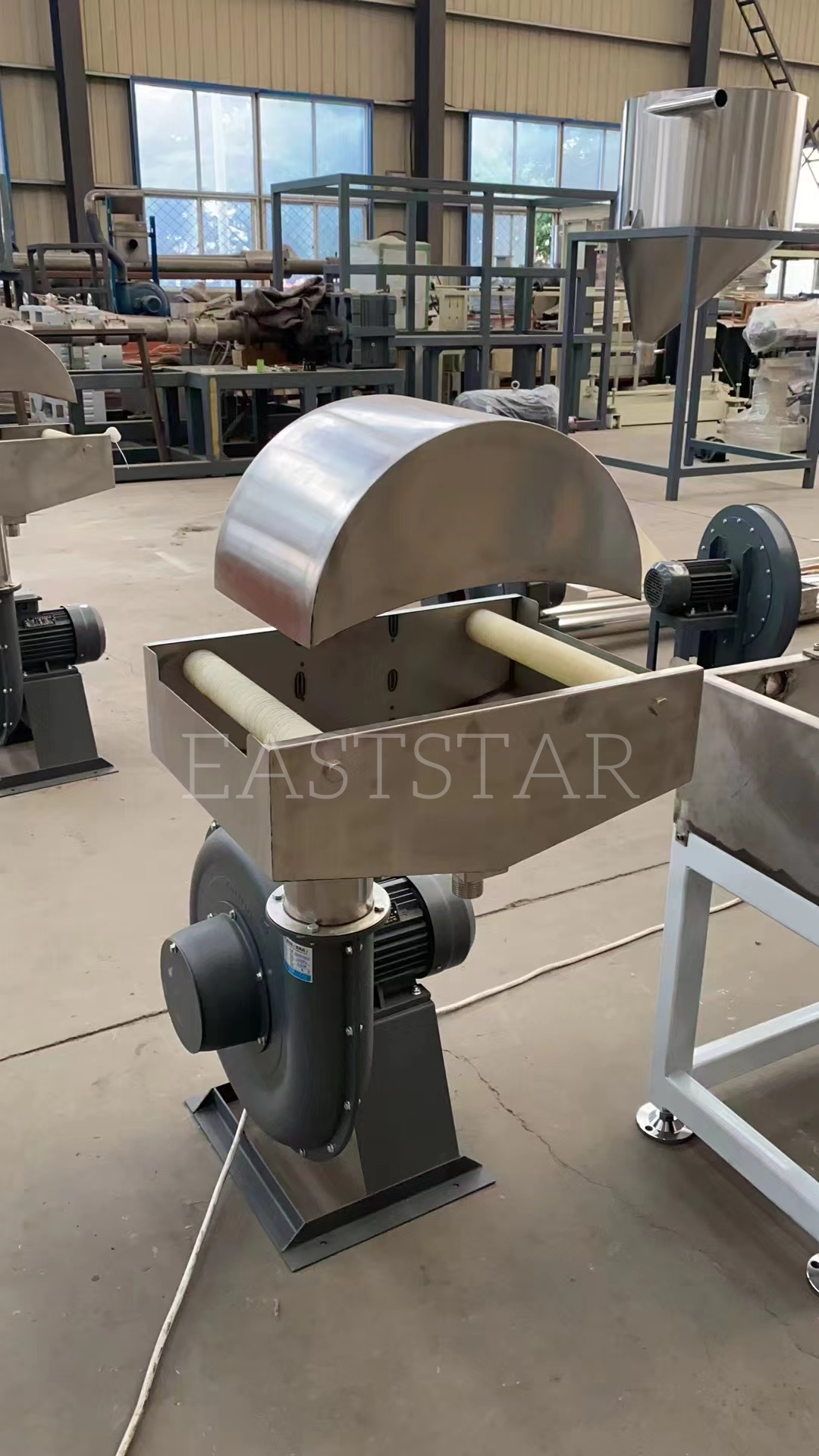

Our technical team is conducting precision assembly of the TSSK65 parallel twin-screw granulator for our Arab client

2025-10-30

Our technical team is conducting precision assembly of the TSSK65 parallel twin-screw granulator for our Arab client

Our production team is currently completing the final assembly phase of this advanced plastic granulation equipment. This twin-screw granulator production project demonstrates our commitment to delivering high-quality pelletizing solutions to the global plastics recycling industry.

The core of this parallel twin-screw granulator is the TSSK65 extruder system, featuring screws with 62mm diameter and 40:1 length-to-diameter ratio. These critical components are manufactured from 40CrNiMoA material, ensuring exceptional durability when processing various plastic materials. The barrel, constructed from 38CrMoALA steel, incorporates 10 heating zones with 6.5kW heating capacity each, providing precise temperature control throughout the plastic granulation process.

Advanced Systems Integration

Our twin-screw granulator integrates multiple sophisticated subsystems to ensure optimal performance. The main drive system employs a Siemens 75kW AC motor coupled with an ABB frequency converter, delivering maximum screw speeds of 600 RPM. The granulation equipment also features a comprehensive vacuum system with water circulation vacuum pump capable of 48m³/hour extraction capacity, effectively removing volatiles during processing.

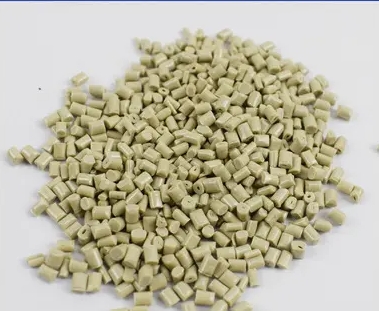

The parallel twin-screw granulator incorporates a dual-spiral metering feeder with 2.2kW power and 17:1 speed ratio, ensuring consistent material feeding. For the cutting section, the plastic granulation system utilizes a hot-cut template with 72 holes of 2.8mm diameter, complemented by four cutting blades in the rapier assembly. Two high-pressure blowers (5.5kW and 4kW) efficiently transport pellets through stainless steel piping to the separation and collection systems.

Precision Engineering and Quality Assurance

Every aspect of this twin-screw granulator reflects our dedication to engineering excellence. The oil lubrication system with 0.55kW pump motor and SL-411 condenser ensures smooth operation of all moving parts. The soft water cooling system with 0.55kW cooling pump maintains optimal processing temperatures throughout the plastic granulation equipment.

We are particularly proud of the control systems implemented in this parallel twin-screw granulator. The electrical cabinet utilizes Schneider contactors and Siemens motors, providing reliable operation under three-phase 380V 50Hz power supply. The comprehensive granulator production includes auxiliary components such as vibration screens, storage hoppers, and a complete set of specialized tools for maintenance and operation.

We anticipate this twin-screw plastic granulation equipment will significantly enhance our client's production capabilities when it becomes operational.