- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Innovative technologies drive PVC edge banding production, achieving efficient and precise manufacturing.

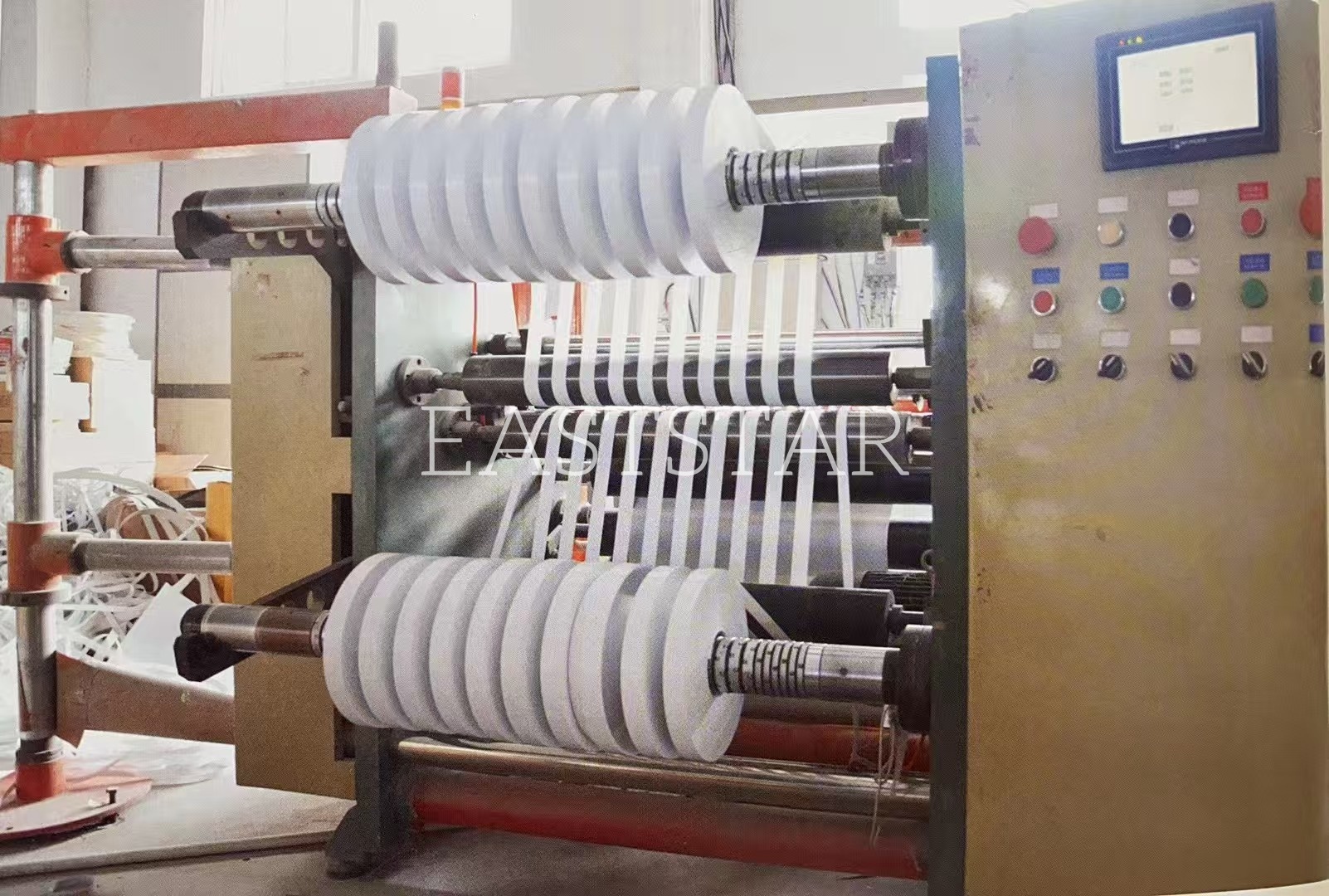

Qingdao, China - QINGDAO EASTSTAR, a professional extrusion equipment manufacturer, recently launched a new generation of PVC edge banding production lines. This solution is designed to meet the sophisticated surface treatment requirements of the furniture manufacturing industry. This advanced PVC edge banding equipment integrates multiple innovative technologies to produce high-quality products with stable dimensions and uniform color, meeting the dual demands of modern furniture manufacturing for both aesthetics and practicality.

The core of a modern PVC edge banding production line lies in precision extrusion technology. The equipment utilizes a specially designed screw and barrel structure to ensure complete plasticization of the PVC material during processing. A temperature control system with an accuracy of ±1°C ensures stable material flow, which is crucial for producing PVC edge banding with uniform thickness. The entire line also includes an automatic mixing device that precisely mixes raw materials and color masterbatches according to preset ratios, ensuring consistent color throughout each batch.

Intelligent Control System Improves Production Efficiency

The new generation of PVC edge banding equipment is equipped with an intelligent control system, allowing operators to monitor production parameters in real time via a touchscreen. The system automatically records optimal process parameters and can be recalled with a single click when reproducing similar products, significantly reducing commissioning time. This intelligent design ensures stable operation of the PVC edge banding production line even for novice operators, significantly reducing the company's reliance on skilled labor.

A multi-stage cooling and shaping device is installed downstream of the production line. By precisely controlling water temperature and flow rate, the PVC edge banding is quickly shaped and retains its shape after leaving the mold. A precise pulling mechanism provides smooth pulling force to prevent stretching and deformation. For PVC edge banding with specialized surface requirements, the line can also be equipped with optional embossing, printing, or coating modules to achieve a variety of decorative effects, such as wood grain and stone pattern.

Adapting to Diverse Market Demands

This PVC edge banding equipment offers excellent production flexibility. By changing molds and adjusting process parameters, it can produce products of varying thicknesses (0.3-3mm) and widths (10-80mm). This flexibility enables manufacturers to quickly adjust product specifications based on market demand, producing PVC edge banding for diverse applications such as cabinets, office furniture, and interior decoration. The equipment is also optimized for the use of recycled materials, helping customers reduce raw material costs.

The production line is designed with energy conservation and environmental protection in mind, utilizing a high-efficiency servo motor drive, resulting in over 30% energy savings compared to traditional equipment. The enclosed heating coil reduces heat loss and improves the workshop environment. The low-noise design meets the high standards of modern factories and embodies the perfect combination of machine manufacturing and user-friendly design.

For more information, please contact us.

+86-132 0641 0288

dongfangzhixing697@gmail.com