- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Hdpe Geocell Sheet Machine Manufacturers, Suppliers, Factory

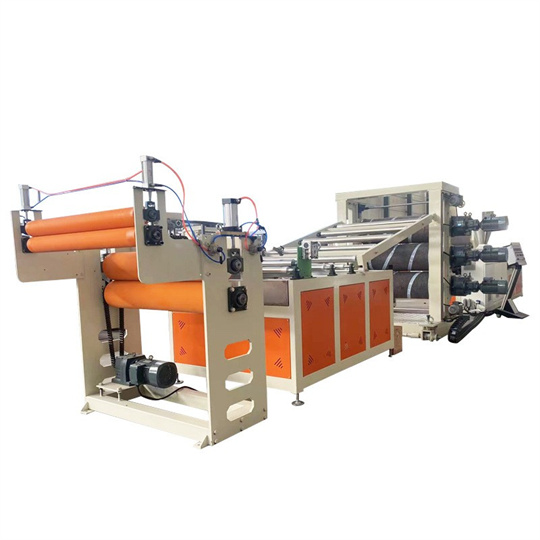

Our pursuit and corporation aim should be to "Always satisfy our consumer requirements". We carry on to build and style and design remarkable quality items for both our outdated and new clients and reach a win-win prospect for our clients at the same time as us for Hdpe Geocell Sheet Machine,Hdpe Geocell Sheet Machine Extrusion Machine,Hdpe Geomembrane Geocell Sheet Machine,Geocell Extrusion Line,100mm Geocell Extrusion Machine, Our tenet is "Reasonable price ranges, efficient manufacturing time and finest service" We hope to cooperate with additional consumers for mutual advancement and positive aspects.

Hdpe Geocell Sheet Machine, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you.

Hot Products

PS Sheet Extrusion Line

Eaststar, a leading manufacturer in the industry, operates a cutting-edge factory dedicated to the production of PS Sheet Extrusion Lines. Tailored to specific requirements, the production line is capable of producing precise plastic sheets with widths ranging from 600 to 4000 millimeters and thicknesses from 3 to 40 millimeters. Equipped with high-plasticization single-screw extrusion technology, hydraulic automatic screen changers, and an adjustable hanger-type mold, Eaststar PS Sheet Extrusion Line ensures top-notch precision and efficiency.PS Blister Packaging Sheet Machine

Eaststar, a trusted manufacturer from China, is an expert in producing top-quality PS blister packaging sheet machines. The PS blister packaging sheet machines from Dongfang Star are widely used in various industries and are known for their accuracy, precision, and durability. So, if you're looking for a high-quality PS blister packaging sheet machine, consider Eaststar - you won't be disappointed!PS Sheet Blister Machine

Eaststar stands as a leading supplier in the industry, offering top-of-the-line PS Sheet Blister Machines.Our PS Sheet Blister Machines are designed to produce high-quality blister packaging with ease and efficiency, making them an invaluable asset for businesses in need of top-tier packaging solutions. Trust Eaststar for cutting-edge machinery that ensures your products are packaged with precision and care.HDPE Geocell Sheet Production Line

In the realm of geotechnical engineering, our high-quality HDPE Geocell Sheet Production Line, proudly made in China, stands as a beacon of excellence. With precision engineering and meticulous craftsmanship, it ensures robust and reliable performance, meeting the stringent demands of geotechnical projects worldwide. Trust in our production line to deliver a superior and efficient solution for your HDPE geocell sheet manufacturing needs. Elevate your geotechnical endeavors with our advanced production technology.PVC Anti-static Board Equipment

PVC Anti-static Board Equipment: The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.High Quality Aluminum Plastic Panel Recycling Equipment

Qingdao East Star Plastic Machinery Co., Ltd. is mainly engaged in sheet material extruder equipment. High Quality Aluminum Plastic Panel Recycling Equipment is one of the important products produced by our company. We can match the equipment with corresponding output according to customer requirements. Friends from all over the world are welcome to purchase equipment.