- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Equipment Vehicle Floor Protection Manufacturers, Suppliers, Factory

While in the past few years, our organization absorbed and digested sophisticated technologies both equally at home and abroad. Meanwhile, our corporation staffs a group of experts devoted to your advancement of Equipment Vehicle Floor Protection,1000mm TPE Car Mats,Heavy Duty Van Mats,Anti-Slip Truck Floor Mats,TPE Van Liners 1000mm, As an expert specialized with this field, we have been committed to solving any problem of significant temperature protection for users.

Equipment Vehicle Floor Protection, In order to make more people know our items and to enlarge our market, we've got devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

Hot Products

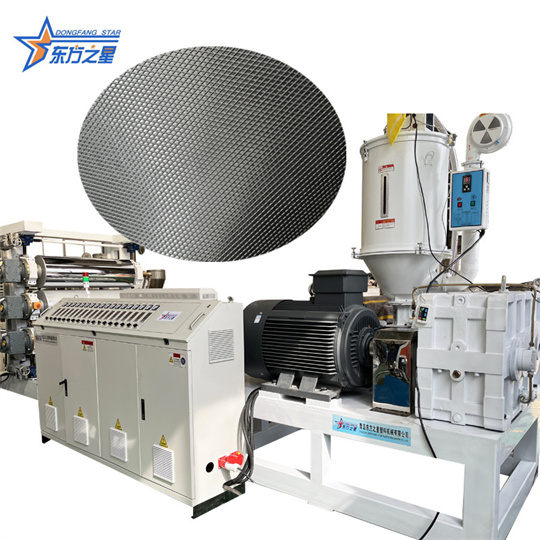

PVC Soft Curtain Extrusion Machine

Eaststar, a reputable and reliable manufacturer based in China, offers top-of-the-line PVC Soft Curtain Extrusion Machines that are designed to meet the needs and specifications of various clients.Car Mat Production Line

As trusted suppliers, they provide top-quality Car Mat Production Line to various car brand suppliers worldwide. With a strong track record of exports to countries such as South Korea, Japan, and Egypt, Eaststar's factory is at the forefront of automotive interior solutions. Choose Eaststar for reliable and efficient car mat production technology.Seedling Tray Seeder Making Machine

Based in China, Eaststar is a prominent supplier of Seedling Tray Seeder Making Machines. These machines are meticulously crafted to meet the demands of nurseries and agricultural enterprises. Eaststar's state-of-the-art factory employs cutting-edge technology to manufacture high-quality equipment. Collaborating with trusted suppliers, Eaststar ensures the use of top-notch components, ensuring the efficiency and durability of their machinery. With a reputation for advanced technology and reliable production capabilities, Eaststar is a preferred choice for suppliers worldwide in need of top-grade Seedling Tray Seeder Making Machines.Seedling Box Plug Tray equipment

Seedling Box Plug Tray equipment technical parameter Specification width of used sheet: 300~320mm, thickness: 0.8~2mm. Forming area (maximum): 400*600 mm, working efficiency of 15~20 times / minute. Power used: three-phase four-wire 380 volts, maximum power 25KW Hydraulic pressure: 100T External size (mm) length, width and height) 3600mm*980mm*1500mmSoft Pvc Sheet Single Screw Extruder Making Machine

Soft Pvc Sheet Single Screw Extruder Making Machine : The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.Soft Pvc Turble Back Board Equipment

The most important part of Soft Pvc Turble Back Board Equipment is the three-roller forming machine, which has two smooth rollers and a tortoise shell roller in the middle.The processing procedures of the tortoise shell roller include: rough turning, dynamic balancing, fine turning, grinding, electroplating, engraving, frosting, and fine mirror grinding. The time for engraving the roller is relatively long, so the delivery cycle of the whole equipment is relatively long. Manufacturers who need to process and customize tortoise shell equipment must place orders in advance.