- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

TPE+non-woven Fabric Composite Co-extrusion-waterstop Production Line

TPE+non-woven Fabric Composite Co-extrusion-waterstop Production Line uses co-extrusion to merge a TPE core with a non-woven fabric layer, creating flexible, durable waterstops for concrete joints. The process ensures high-quality, consistent output, ideal for construction applications requiring reliable waterproofing.

Model:SJ-55/30:1

Send Inquiry

TPE+non-woven Fabric Composite Co-extrusion-waterstop Production Line

Equipment List

1. SJ-55/30 single-screw extruder (1 unit)

2. Upper and lower unwinding devices (2 units each)

3. Die and screen changer (1 set)

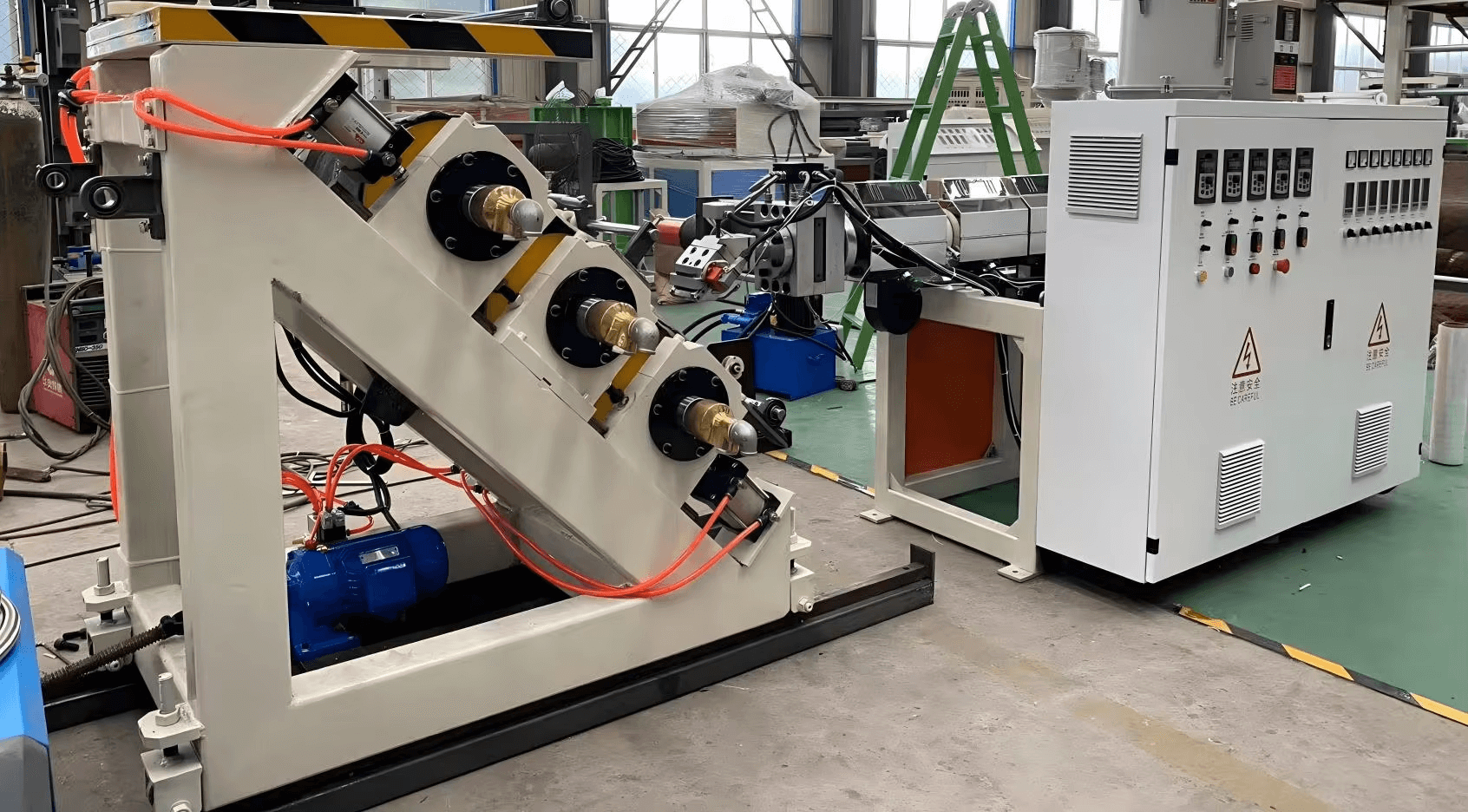

4. 500mm L three-roll calender (1 unit)

5. Roller temperature control system (1 unit)

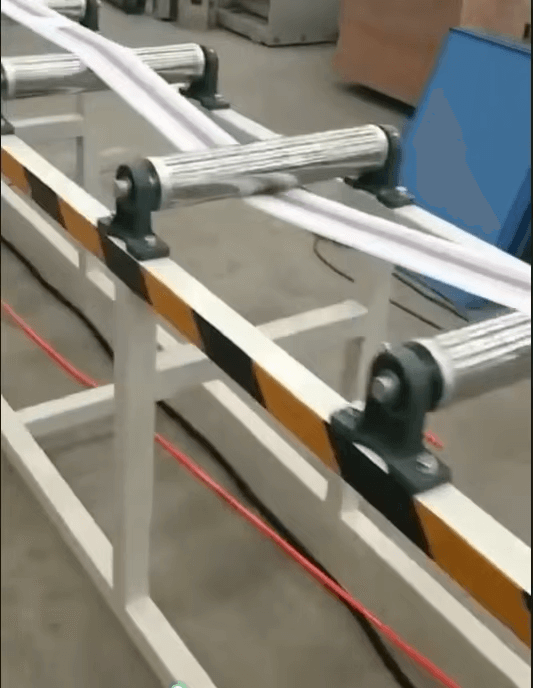

6. Cooling bracket and trimming system (1 set)

7. Haul-off (1 unit)

8. Winder (1 unit)

9. Complete electrical control system (1 set)

Equipment display (part)

Screw, Barrel, and Temperature Control

Screw Material: 38CrMoAL, Nitrided Steel

Screw Hardness: HV950

Barrel Material: Wear-Resistant Barrel Material, Nitrided Steel

Barrel Hardness: HV1050

Screw Diameter: 55mm

L/D Ratio: 30/1

Main Motor Power: 15kW

Main Motor Heating Power: 12kW

Barrel Heating: Cast Aluminum or Ceramic

Temperature Control: Automatic, Fan-Forced Cooling

Calender

Roller diameter: 300mm

Roller effective width: 400mm

Roller material: 45 steel

Roller structure: Qingdao Roller Manufacturing or Xuzhou Saite Machinery's special multi-channel design

Coaxiality: ≤0.005mm

Roller surface finish: Ra ≤0.016µm

Roller surface hardness: HRC58-62

Chromium plating thickness: 0.08mm

Drive reduction gearbox: Redson or Congli

Drive power: 3 x 1.5kW

Speed control: Invt inverter

Three-roller gap adjustment: Cylinder adjustment, safety emergency stop switch, synchronous control system

Three-roller configuration: 45° tilt

Three-roller wall panel: Integral steel plate welding

Three-roller spherical roller bearings: Harbin Bearing or Wafangdian Bearing

Swivel joint: Sino-foreign joint venture

Tractor

Specifications: Ø160 x 400mm

Material: Nitrile rubber rollers

Drive: Reducer

Power: 1 x 1.1kW

Control: INVT variable frequency drive

Clamping method: Pneumatic

Synchronized with three rollers or independently

Winder

Drive Torque

Type: Dual-station

Control: Automatic fixed-length counting

Rewinding diameter: 50mm

Paper tube core specification: 2-inch outer jacket

Finished product display