- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Soft PVC Sheet Making Machine Manufacturers, Suppliers, Factory

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Soft PVC Sheet Making Machine,Soft Pvc Sheet Single Screw Extruder Making Machine,PVC sheet extruder machine, Adhering into the business enterprise philosophy of 'customer initial, forge ahead', we sincerely welcome purchasers from at your home and abroad to cooperate with us.

Soft PVC Sheet Making Machine, With the advanced workshop, qualified design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our merchandise are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

Hot Products

PET Plastic Sheet Extrusion Machine

Eaststar is an experienced factory and manufacturer of PET plastic sheet extrusion machines. With cutting-edge technology and state-of-the-art equipment, their machines are renowned for their reliability, efficiency, and high-quality output. Whether you are in the packaging, automotive, or construction industry, Eaststar has the perfect PET plastic sheet extrusion machine for you. Trust in their expertise and technical precision to take your business to the next level.PP Heat Insulation Equipment

PP Heat Insulation EquipmentPET Root Plant Root Protection Equipment

root controldevice is mainly in accordance with the working principle of hot pressing equipment design. Root control equipment can also produce water spraying sheets 1. PET Root Plant Root Protection Equipment is mainly in accordance with the working principle of hot pressing equipment design, process is: sheet —— feeding —— heating —— pressing —— pressure —— molding —— cutting steps, appearance neat and practical, plate processing all processing center, ensure the accuracy of all hole size, column and pin appearance are hard chromium quenching treatment, ensure the sliding and wear resistance, machine system edited into manual and automatic two parts, in manual case all action can be single operation. 2: The feed motor is driven by a servo motor with a power of 2 kW. 3: feeding reducer motor 0.55KW and 1:10 special reducer, to ensure the stability of feeding speed! 4: Ceramic heating block: new ceramic heating block, heating fast and low power consumption, the temperature can be adjusted freely, according to the thickness of different materials. 5: Other mechanical parts are produced and processed by our company. Automatic control system adopts: Delta PLC control, 6: The machine adopts hydraulic balanced distribution design, the overall balance is better, to solve the situation of the high and low in the production to prolong the use time of the mold.Soft Pvc Turble Back Board Equipment

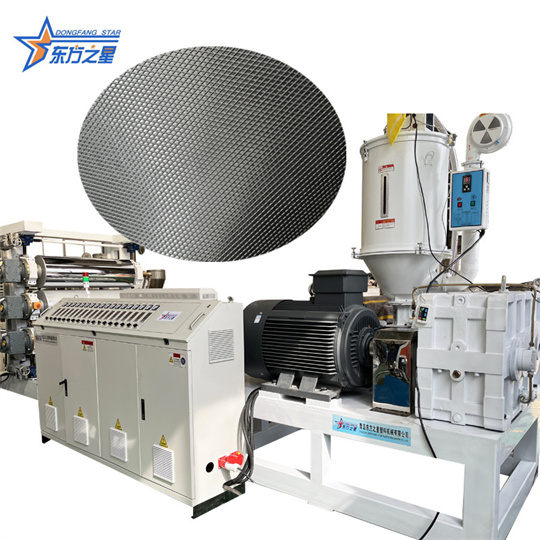

The most important part of Soft Pvc Turble Back Board Equipment is the three-roller forming machine, which has two smooth rollers and a tortoise shell roller in the middle.The processing procedures of the tortoise shell roller include: rough turning, dynamic balancing, fine turning, grinding, electroplating, engraving, frosting, and fine mirror grinding. The time for engraving the roller is relatively long, so the delivery cycle of the whole equipment is relatively long. Manufacturers who need to process and customize tortoise shell equipment must place orders in advance.Pa Sheet Extrusion Line Single Screw Extruder Machine

Pa Sheet Extrusion Line Single Screw Extruder MachineTPE-1000mm anti-slip mat equipment car floor mats

TPE-1000mm anti-slip mat equipment car floor mats: The equipment mainly consists of a single-screw extruder, a three-roller calender, a 6-meter cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device.