- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

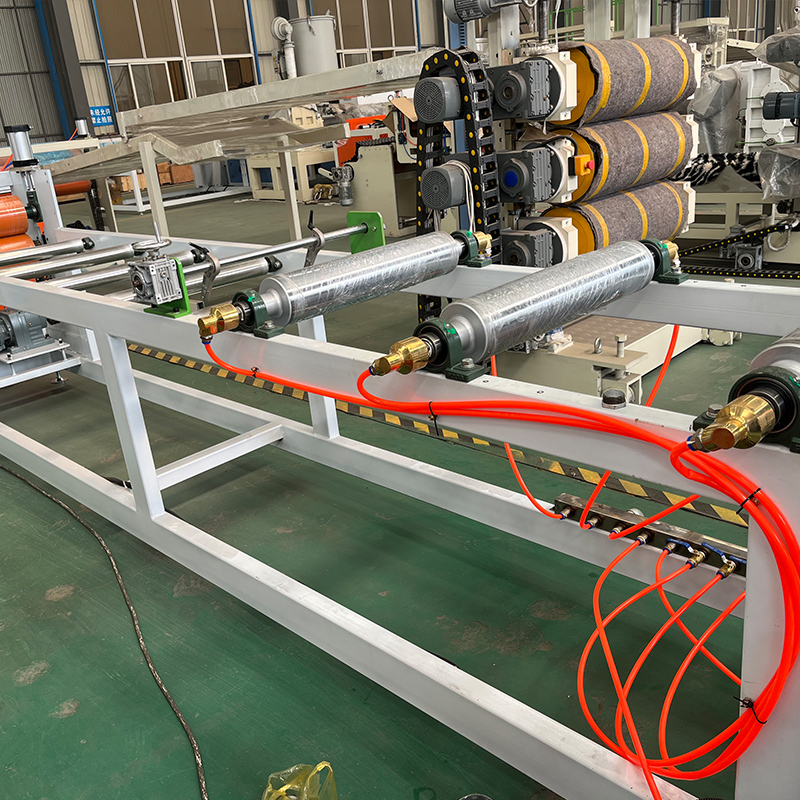

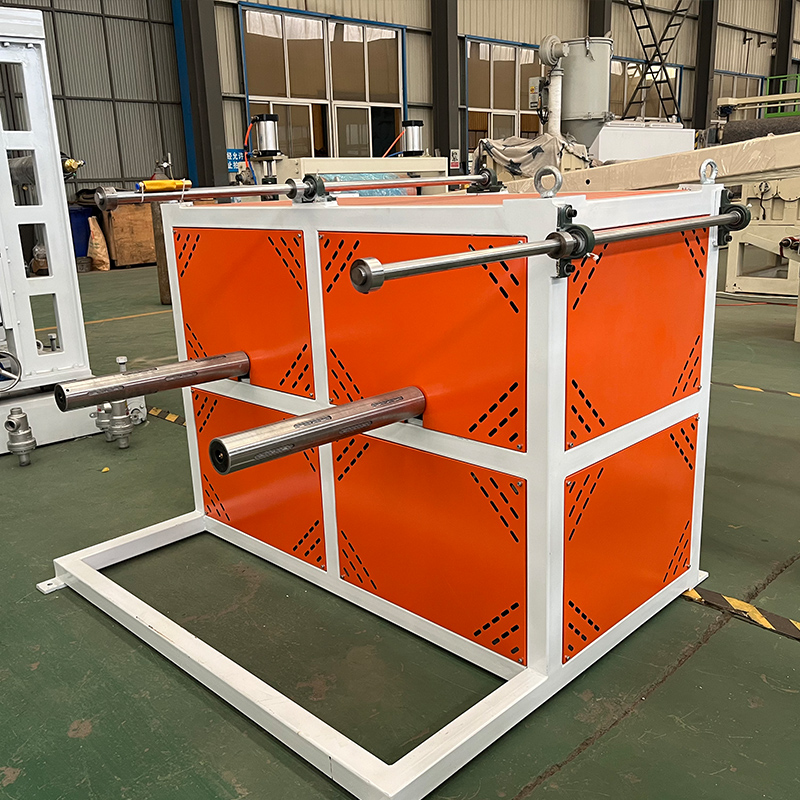

Pa Sheet Extrusion Line Single Screw Extruder Machine

Pa Sheet Extrusion Line Single Screw Extruder Machine

Model:SJ65/33

Send Inquiry

Pa Sheet Extrusion Line Single Screw Extruder Machine

The production process of PA sheet equipment involves multiple links such as raw material processing, melt extrusion, molding, cooling and shaping, traction and cutting, etc.

Raw material selection

The main raw material is PA resin (such as PA6, PA66, etc.), and additives (such as plasticizers, flame retardants, masterbatches, reinforcing fibers, etc.) can be added according to product requirements.

Key requirements: The raw materials must meet the purity, molecular weight distribution and other indicators to avoid impurities affecting the performance of the sheet.

Raw material drying

PA resin has strong hygroscopicity and needs to be pre-treated by hot air dryer or vacuum dryer:

Drying temperature: 80-120℃ (adjusted according to PA type, such as PA6 is generally 80-100℃, PA66 is 100-120℃).

Drying time: 4-8 hours, ensure that the moisture content is less than 0.1% to avoid bubbles or degradation during extrusion.