- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China PE PP Coated Pipe Making Machine Manufacturers, Suppliers, Factory

That has a sound business credit history, outstanding after-sales service and modern producing facilities, we have earned an superb popularity amid our buyers across the planet for PE PP Coated Pipe Making Machine,PP coated pipe equipment, We invites both you and your company to prosper together with us and share a brilliant long run in worldwide market place.

PE PP Coated Pipe Making Machine, We always insist on the management tenet of "Quality is first, Technology is basis, Honesty and Innovation".We've been able to develop new products and solutions continuously to a higher level to satisfy different needs of customers.

Hot Products

ABS Sheet Board Machine

Eaststar, a prominent manufacturer based in China, leads the industry with its state-of-the-art ABS Sheet Board Machine. With a focus on precision engineering, our factory excels in crafting high-quality machinery tailored for efficient ABS sheet board production. The machine, equipped with advanced components, facilitates the transformation of raw ABS material into durable and versatile sheets. Eaststar is the trusted choice for businesses seeking top-tier equipment for ABS sheet board manufacturing.ABS Sheet Extrusion Line

Eaststar is a distinguished supplier known for its state-of-the-art ABS Sheet Extrusion Line. With a reputation for excellence, their factory is equipped with advanced technology and a skilled workforce dedicated to producing high-quality ABS sheets. The combination of their precision engineering and commitment to superior production methods establishes Eaststar as a trusted industry leader in ABS sheet extrusion.Car PVC Flooring Extrusion Machine

Eaststar, a reputable manufacturer in the industry, specializes in producing Car PVC Flooring Extrusion Machines. What sets Eaststar apart is their commitment to providing high-quality machinery at a competitive price point. The Car PVC Flooring Extrusion Machines manufactured by Eaststar are designed to meet the precise requirements of automotive PVC flooring production, ensuring efficiency and precision in every extrusion.Plastic Root Prune Flower Pots Making Machine

Eaststar is a renowned supplier of durable Plastic Root Prune Flower Pots Making Machine. Built to last, Eaststar's machines ensure a seamless and reliable production process, making them a valuable asset for nurseries and gardening businesses. With Eaststar as your supplier, you can trust in the longevity and performance of their Plastic Root Prune Flower Pot Making Machines, enabling you to meet your production needs with confidence and ease.Plastic Seedling Tray Machinery

Eaststar is a leading manufacturer in China specializing in the production of advanced Plastic Seedling Tray Machinery. With a state-of-the-art factory and a commitment to innovation, Eaststar has established itself as a reliable supplier in the industry. Their machinery is designed to meet the specific demands of producing high-quality seedling trays, catering to the needs of nurseries and agricultural enterprises.PVC Antistatic Sheet Extruder Equipment

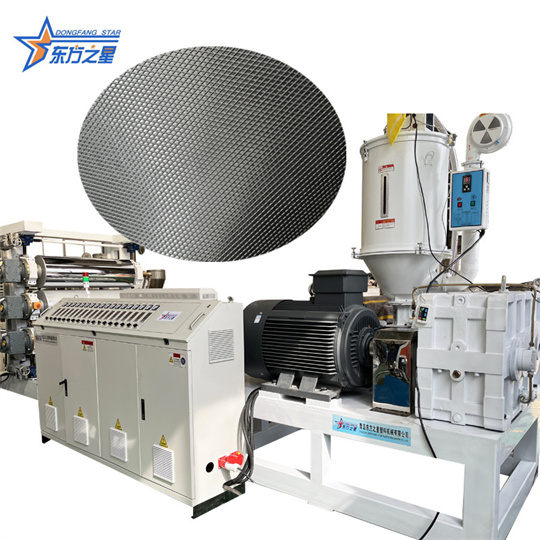

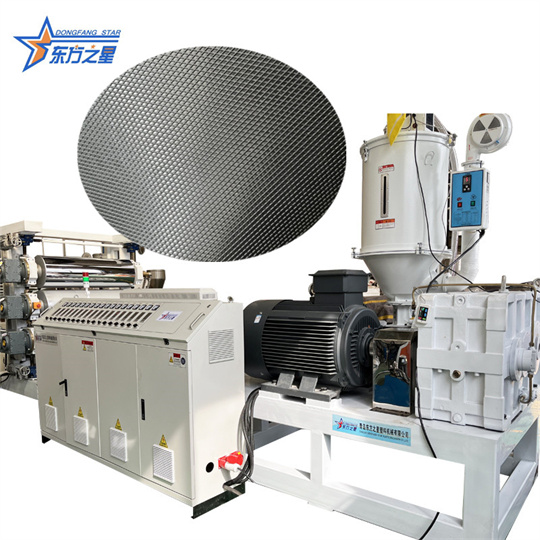

PVC Antistatic Sheet Extruder Equipment: The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.