- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

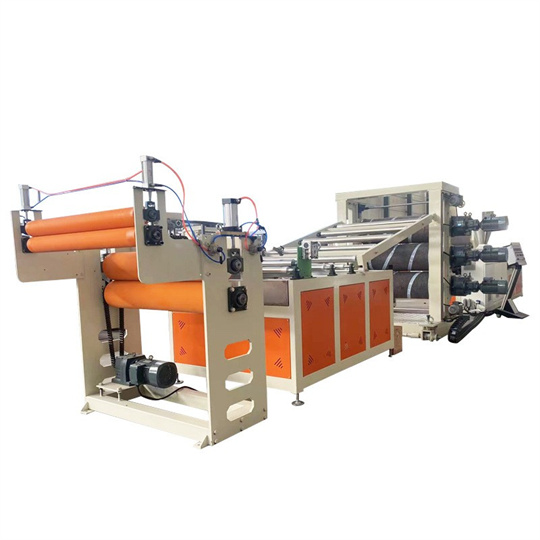

China PVC Transparent Sheet Extruder production line Manufacturers, Suppliers, Factory

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for PVC Transparent Sheet Extruder production line,pvc sheet extruder machine, The continual availability of substantial grade goods in combination with our exceptional pre- and after-sales support ensures strong competitiveness in an increasingly globalized marketplace.

PVC Transparent Sheet Extruder production line, We are eager to cooperate with foreign companies which care much on the real quality, stable supply, strong capability and good service. We can offer the most competitive price with high quality,because we are much MORE PROFESSIONAL. You are welcomed to visit our company at any time.

Hot Products

PP Sheet Board Machine

Eaststar, a distinguished manufacturer in the industry, operates a cutting-edge factory dedicated to the production of PP sheet board machines. Renowned for their commitment to excellence, Eaststar designs and manufactures machinery that sets the standard for precision and quality in PP sheet production. With a reputation for innovation and a world-class manufacturing facility, Eaststar stands as a leading force in providing top-tier solutions for the production of PP sheet boards.PE Plastic Sheet Extrusion Machine

Eaststar, located in China, specializes in crafting customized PE Plastic Sheet Extrusion Machines. With a keen focus on precision and flexibility, these machines are designed to meet a wide range of specific requirements. Whether you need plastic sheets for packaging, construction, or any other application, Eaststar expertise ensures that their extrusion machines deliver top quality results. Trust in Eaststar to provide tailored solutions that exemplify the pinnacle of plastic sheet production technology.Geocell Grid Extrusion Machine

Eaststar, a reputable supplier in the industry, specializes in providing top-of-the-line Geocell Grid Extrusion Machines. These advanced machines are designed for the precise manufacturing of geocell grids, essential for various civil engineering and construction applications. Any inquiries and problems please feel free to send emails to us and we will reply you soon.Pvc Crystal Plate Equipment

Pvc Crystal Plate Equipment can produce PVC transparent plastic sheets with a width of 800-1200 mm and a thickness of 0.8-5 mm.Tree Root Control Equipment

Tree Root Control Equipment is mainly in accordance with the working principle of hot pressing equipment design. Root control equipment can also produce water spraying sheets 1. PET Root Plant Root Protection Equipment is mainly in accordance with the working principle of hot pressing equipment design, process is: sheet —— feeding —— heating —— pressing —— pressure —— molding —— cutting steps, appearance neat and practical, plate processing all processing center, ensure the accuracy of all hole size, column and pin appearance are hard chromium quenching treatment, ensure the sliding and wear resistance, machine system edited into manual and automatic two parts, in manual case all action can be single operation. 2: The feed motor is driven by a servo motor with a power of 2 kW. 3: feeding reducer motor 0.55KW and 1:10 special reducer, to ensure the stability of feeding speed! 4: Ceramic heating block: new ceramic heating block, heating fast and low power consumption, the temperature can be adjusted freely, according to the thickness of different materials. 5: Other mechanical parts are produced and processed by our company. Automatic control system adopts: Delta PLC control, 6: The machine adopts hydraulic balanced distribution design, the overall balance is better, to solve the situation of the high and low in the production to prolong the use time of the mold.2.4m Manure Removal Belt Extrusion Line

Professional Manufacturer of 2.4m Manure Removal Belt Extrusion Line | Providing Key Equipment for Modern Poultry and Livestock Farming In modern intensive livestock (poultry and pig) farms, automated manure removal systems are central to ensuring animal welfare, improving environmental hygiene, and increasing operational efficiency. High-quality manure belts are a key component of these systems. Our 2.4-meter manure belt sheet extrusion line is specifically designed to produce these wide, high-strength PP (polypropylene) or PE (polyethylene) sheets.