- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China PVC Sealing Strip Equipment Manufacturers, Suppliers, Factory

We emphasize development and introduce new products into the market every year for PVC Sealing Strip Equipment,Sealing fire protection strip equipment, Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we will become long-term partners.

PVC Sealing Strip Equipment, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

Hot Products

PVC Car Floor Mats Making Machine

Looking to streamline your PVC car floor mats production? Our top-tier PVC Car Floor Mats Making Machine, offered by a trusted supplier, is now available with an exclusive discount. This specialized machinery is designed to efficiently and precisely manufacture high-quality car floor mats from PVC materials. Don't miss out on this opportunity to enhance your manufacturing process with our discounted PVC Car Floor Mats Making Machine from our reliable supplier.Seedling Pot Tray Making Machine

Collaborating with reputable suppliers, Eaststar ensures the use of top-notch components, guaranteeing the efficiency and durability of their machinery. Suppliers worldwide turn to Eaststar for their advanced technology and reliable production capabilities in Seedling Pot Tray Making Machines.PVC Anti-static Board Equipment

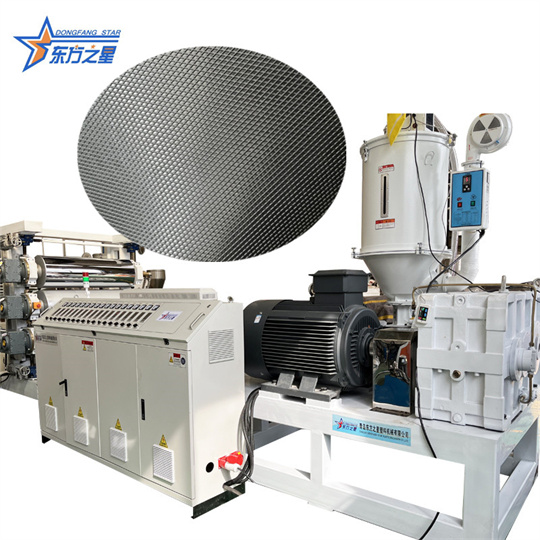

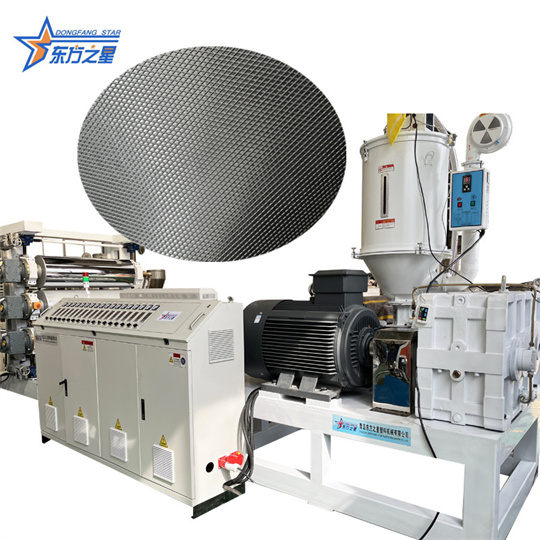

PVC Anti-static Board Equipment: The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.PVC Antistatic Sheet Extruder Equipment

PVC Antistatic Sheet Extruder Equipment: The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.Soft Pvc Sheet Single Screw Extruder Making Machine

Soft Pvc Sheet Single Screw Extruder Making Machine : The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.ABS/HIPS 2000mm Wide Plastic Sheet Extrusion Production Line

Our EASTSTAR SJ150-HIPS/ABS 2000mm plastic sheet extrusion line is engineered for high-volume production of premium-quality sheets used in appliance casings, signage, and industrial packaging. With robust output of 400-600 kg/h and equipped with SIEMENS & ABB automation, it ensures stable performance and superior surface finish via mirror-finish calendering rolls. Supported by our in-house R&D and manufacturing facilities, we deliver reliable, custom-configured solutions. Having successfully supplied turnkey lines across Southeast Asia and the Middle East, we maintain streamlined production for timely global delivery. This extruder represents an optimal balance of productivity, precision, and durability for expanding your sheet manufacturing capabilities.