- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Plastic Geocells Making Machine Manufacturers, Suppliers, Factory

Our enterprise insists all along the standard policy of "product good quality is base of organization survival; client gratification could be the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff" and the consistent purpose of "reputation to start with, purchaser first" for Plastic Geocells Making Machine,Geocells Making Machine,Smooth Geocell Machine,Stabilizer Geocell Making Machine,Geocell Ground Grid Making Machine, Our items are regularly supplied to lots of Groups and lots of Factories. Meanwhile, our products are sold to the USA, Italy, Singapore, Malaysia, Russia, Poland, plus the Middle East.

Plastic Geocells Making Machine, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, be sure to click the button to acquire additional nformation.

Hot Products

PVC Car Floor Mats Making Machine

Looking to streamline your PVC car floor mats production? Our top-tier PVC Car Floor Mats Making Machine, offered by a trusted supplier, is now available with an exclusive discount. This specialized machinery is designed to efficiently and precisely manufacture high-quality car floor mats from PVC materials. Don't miss out on this opportunity to enhance your manufacturing process with our discounted PVC Car Floor Mats Making Machine from our reliable supplier.Root Controller Making Machine

Eaststar, a renowned manufacturer based in China, specializes in crafting high-quality Root Controller Making Machines. Our state-of-the-art factory and commitment to excellence have positioned Eaststar as a trusted supplier in the agricultural machinery industry.PE Aluminum-Plastic Composite Panel Production Line

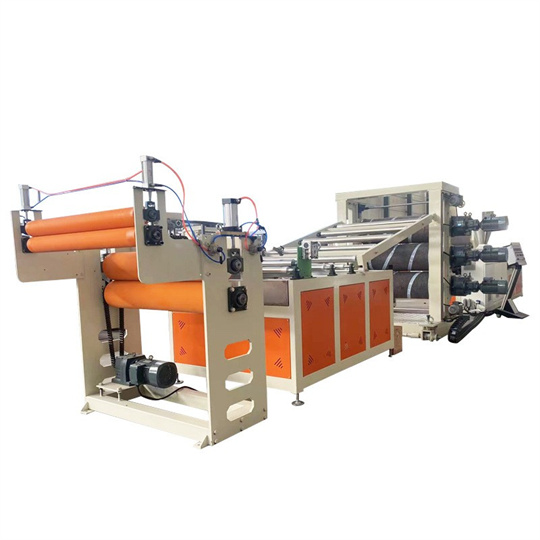

PE Aluminum-Plastic Composite Panel Production Line (also known as aluminum-plastic panel), as a new building material, and has been quickly favored by people for its economy, the diversity of optional colors, convenient construction methods, excellent processing performance, excellent fire resistance and noble quality. The unique properties of aluminum-plastic composite board determine its wide range of uses: it can be used for building exterior walls, curtain wall panels, renovation of old buildings, indoor wall and ceiling decoration, advertising signs, display stands, purification and dust prevention projects. It belongs to a new type of building material. The products produced by the equipment are mainly suitable for the inner and outer wall PE composite board, the thickness of the product is from 1-6mm, the width of 1200-1500mm two models, the thickness of the aluminum foil is from 0.03-0.5mm, and the bonding process of polymer film or glue can be selected. The equipment has the advantages of one molding, stable extrusion, firm compound, good flatness and so on.HDPE Sheet Geogrid Equipment

HDPE Sheet Geogrid Equipment is used to produce geocells. The first step of this product is to produce sheets, and then the sheets are cut online, and then the plastic sheets are connected through ultrasonic welding and other methodsPA POM Sheet Extruder Machine

The PA POM Sheet Extruder Machine of: single-screw extruder, three-roller calender, cooling bracket with automatic trimming device, rubber roller traction machine, and winding machine. Products of different specifications can be produced according to different requirements of customers. Sheets with different surfaces can be produced with smooth, orange peel, and matte surfaces.Sheet Three-roller Calender Forming Machine

Sheet Three-roller Calender Forming Machine is mainly composed of five parts: super mirror roller part, motor drive system, gap adjustment system, electrical control system, and frame. Rollers with different widths and thicknesses can be ordered and produced according to customer requirements. The surface of the roller can be smooth, matte, orange peel, diamond, or tortoise. The three-roller calender can be used for a variety of plastic sheets. Calender cooling molding: used for extrusion of PE, PP, PVC, ABS, PC, POM and other materials.