- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

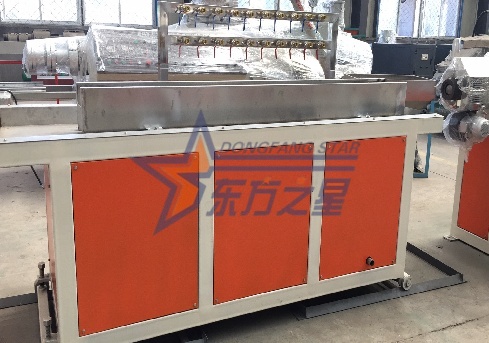

Qingdao Eaststar PVC welding rod production line is practical and easy to use, making it ideal for plastic processing manufacturers.

In the PVC welding industry, welding rods are a daily consumable. Producing them in-house ensures quality and helps control costs. Our PVC welding rod production line is compactly designed, requiring minimal space, yet it offers stable output, consistently producing material every day.

Our PVC welding rod extrusion equipment is incredibly easy to learn and operate. The control panel is intuitive and easy to understand; just adjust a few key parameters, and the machine will run smoothly on its own. Normally, you just need to monitor its operation. Changing specifications or performing cleaning is also very simple. The machine is built with high-quality materials, and the main components are very durable. With normal use, maintenance costs are very low, saving you both time and money.

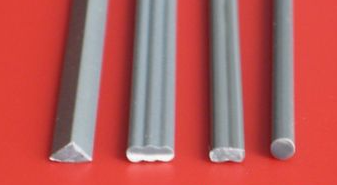

The core of the PVC welding rod production equipment is a single-screw extruder specifically designed for PVC, which maintains stable temperature control and produces 20 to 40 kilograms per hour. The multi-hole die allows for simultaneous extrusion of several rods, with diameters ranging from 3mm to 5mm, and switching between sizes is easy.

The extruded welding rods are first cooled in a water tank, then automatically pulled and wound, and finally neatly coiled onto spools. The length of each coil can be customized. The entire PVC welding rod production line is easy to operate, essentially running automatically after startup, and maintenance is also convenient.

Many factories that manufacture water tanks, air ducts, and advertising signs are using this system. If you frequently need PVC welding rods, producing them yourself is indeed cost-effective. We provide installation and training, guaranteeing that you will learn how to operate the PVC welding rod extruder.

Please feel free to contact us if you have any needs.