- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

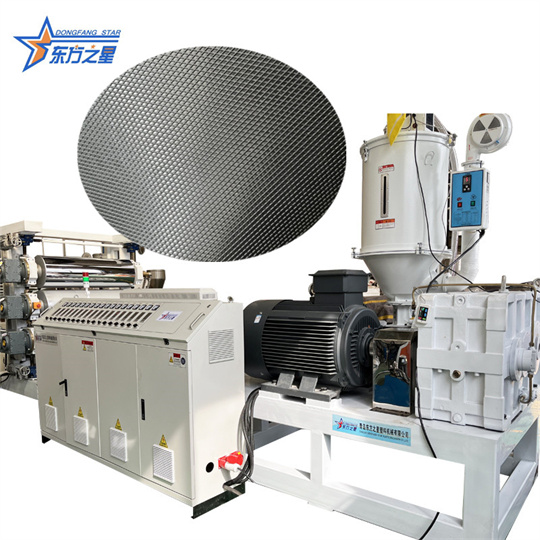

China Soft PVC Sheet Extruder Machine Turtle Pattern Manufacturers, Suppliers, Factory

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for Soft PVC Sheet Extruder Machine Turtle Pattern,PVC turble back board extruder machine,PVC Tortoise Board Equipment, Welcome any within your inquiries and concerns for our products and solutions, we glance ahead to setting up a long-term enterprise partnership along with you within the close to potential. get hold of us today.

Soft PVC Sheet Extruder Machine Turtle Pattern, We pay high attention to customer service, and cherish every customer. Now we have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

Hot Products

PVC Transparent Crystal Board Production Line

PVC Transparent Crystal Board Production Line Eaststar, a reputable manufacturer based in China, specializes in producing state-of-the-art PVC PVC transparent door curtain production line. These cutting-edge machines are meticulously designed to facilitate the extrusion process of PVC materials, particularly for exterior curtain applications.HDPE Waterproof Sheet Extrusion

Eaststar, based in China, is a reputable provider of high-quality HDPE Waterproof Sheet Extrusion equipment. This state-of-the-art machinery is designed to produce top-grade waterproof sheets using high-density polyethylene (HDPE). Trust in Eaststar's expertise and advanced technology to elevate your projects in construction, infrastructure, and other industries that demand superior waterproofing solutions. Choose Eaststar for top-tier HDPE waterproof sheet production in China.PP Heat Insulation Equipment

PP Heat Insulation EquipmentPVC Transparent Soft Door Curtains Machine

PVC Transparent Soft Door Curtains Machine Qingdao EAST STAR Plastic Machinery Co., Ltd. is mainly engaged in plastic sheet equipment. Our company's PVC soft door curtain equipment mainly consists of five parts: super mirror roller part, motor drive system, gap adjustment system, electrical control system, and frame. composition. Our company's PVC soft door curtain equipment can produce PVC transparent soft door curtains with a width of 200-400 mm and a thickness of 0.5-5 mm. This PVC soft door curtain equipment can produce three types of soft door curtains, including glossy, matte and striped, in one machine. It not only achieves multiple uses in one machine and is easy to operate, but also helps customers greatly save costs.HDPE Geogrid extruder production line

HDPE Geogrid extruder production line is used to produce geocells. The first step of this product is to produce sheets, and then the sheets are cut online, and then the plastic sheets are connected through ultrasonic welding and other methodsSoft Pvc Turble Back Board Equipment

The most important part of Soft Pvc Turble Back Board Equipment is the three-roller forming machine, which has two smooth rollers and a tortoise shell roller in the middle.The processing procedures of the tortoise shell roller include: rough turning, dynamic balancing, fine turning, grinding, electroplating, engraving, frosting, and fine mirror grinding. The time for engraving the roller is relatively long, so the delivery cycle of the whole equipment is relatively long. Manufacturers who need to process and customize tortoise shell equipment must place orders in advance.