- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China 60-100kg/h Capacity Manufacturers, Suppliers, Factory

We always think and practice corresponding to the change of circumstance, and grow up. We goal at the achievement of a richer mind and body and also the living for 60-100kg/h Capacity,TPU/PE/PP/PS Processing,Extruder (SJ75-30/1),Three-roll Calender (BF-500 X∮320),Control System (DK-14 zone), For additional facts, please make contact with us as shortly as possible!

60-100kg/h Capacity, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

Hot Products

Planting Trays Seedling Making Machine

Eaststar, a distinguished manufacturer based in China, specializes in the production of high-quality Planting Trays Seedling Making Machines. Collaborating with reputable suppliers, Eaststar sources top-notch components, guaranteeing the exceptional performance and reliability of their machinery. Eaststar's Planting Trays Seedling Making Machines are trusted by suppliers worldwide for their advanced technology and reliable production capabilities.PP Heat Insulation Equipment

PP Heat Insulation EquipmentPVC Edge Banding Equipment

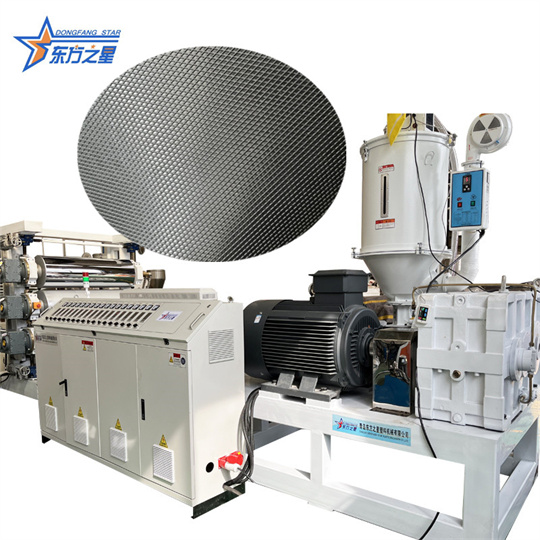

PVC Edge Banding Equipment Technical parameters and configuration 1 Specification model SJ65-28/1 2 screw diameter 65mm 3 Screw length-to-diameter ratio 28:1 4 Screw structure type PVC special screw 5 Barrel structure Barrel integrated 6 screw, barrel material 38CrMOALA 7 Screw and barrel nitriding treatment Nitriding treatment 8 screw and barrel service life is about 3 years 9 Main drive variable frequency motor power 18.5KWSoft PVC Anti-skid Plate Extruder Equipment

Soft PVC anti-skid plate extruder equipment: The equipment mainly consists of a single-screw extruder, a three-roller calender, a 6-meter cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device.High Quality Aluminum Plastic Panel Recycling Equipment

Qingdao East Star Plastic Machinery Co., Ltd. is mainly engaged in sheet material extruder equipment. High Quality Aluminum Plastic Panel Recycling Equipment is one of the important products produced by our company. We can match the equipment with corresponding output according to customer requirements. Friends from all over the world are welcome to purchase equipment.SPC Stone Plastic Flooring Production Line

Choosing Qingdao Eaststar means choosing a reliable partner. Our SJSZ-65/132 SPC Stone Plastic Flooring Production Line has served numerous manufacturers and has received high praise for its superior stability. The fully automated design, coupled with branded components, ensures easy production startup. We not only deliver a high-quality profile production line, but also provide comprehensive services from installation and commissioning to process support, safeguarding your production.