- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Indian Customers Visit Seedling Tray and Root Control Equipment, Discussing Modern Agricultural Planting Solutions

Indian Customers Learn Detailed About the Process Flow and Technical Features of Seedling Tray Production Equipment

Recently, we were honored to host a delegation of customers from India who visited our factory to tour our seedling tray production line and root control equipment. This visit provided us with an excellent opportunity for exchange, fully showcasing the production performance of our seedling tray equipment and allowing us to discuss in depth the specific needs of modern agriculture for planting containers. The Indian customers showed great interest in the seedling tray production technology and root control equipment, paying particular attention to the level of automation and the diversity of product specifications.

Understanding Customer Needs

The Indian customers are primarily engaged in modern agricultural planting and urgently need a complete solution for the large-scale production of high-quality seedling trays and root control devices. Through in-depth discussions, we learned that the customers are particularly concerned about standardized product specifications, production efficiency, and durability. Based on the customers' local large-scale planting needs, we recommended the ZK-300/400 fully automatic seedling tray equipment and the ZK-1000 series root control equipment. These specialized machines can fully meet the customers' production needs for planting containers of different sizes.

Visit to Seedling Tray and Root Control Equipment

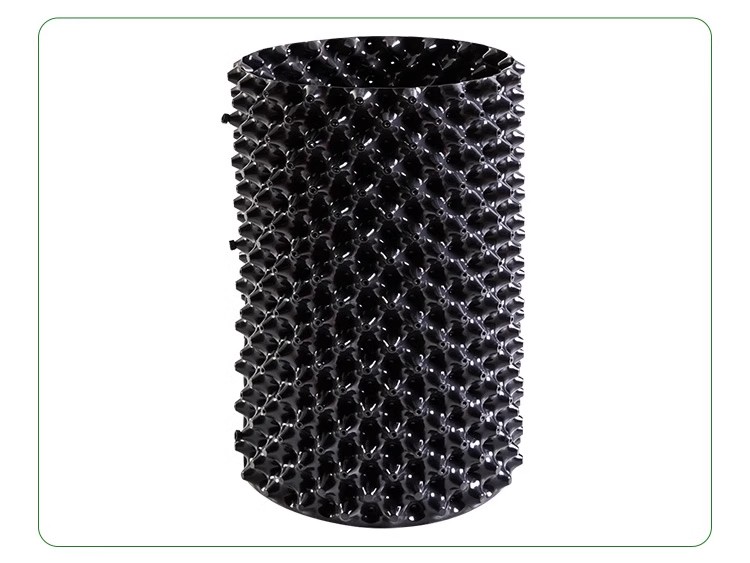

During the visit, we led the client on a site tour of the seedling tray production line and the root control equipment production workshop. At the ZK-300/400 fully automatic seedling tray equipment, the client learned in detail about the entire process from sheet feeding and heating to automatic punching. The technical team demonstrated the equipment's operation, showcasing its high-efficiency production capacity of 15-20 times per minute. Subsequently, the client visited the ZK-1000 series root control equipment, expressing great interest in its continuous hot-pressing process and unlimited length customization function.

Equipment Technical Advantages Showcase

We highlighted the advanced features of the equipment to the client: The ZK-300/400 seedling tray equipment uses PLC programming control, a touchscreen human-machine interface, and a servo drive motor to ensure precise feeding. Far-infrared ceramic heaters combined with solid-state relay temperature control reduce energy consumption by more than 40%. The ZK-1000 root control equipment adopts a hydraulic balance distribution design, solving the problem of left-right height difference and effectively extending the mold's lifespan. The aluminum profile beams are equipped with water flow channels to ensure effective cooling and rapid shaping.

Products

Complete Production Solutions

In addition to molding equipment, we also showcased our matching sheet and roll extrusion equipment, forming a complete industrial chain demonstration from raw materials to finished products. The client expressed appreciation for our one-stop solution, especially the equipment's ability to process various materials such as PVC, PE, PET, PP, and PS, meeting their diverse production needs.

This visit by our Indian clients laid a solid foundation for future cooperation. We believe that through professional seedling tray and root control device equipment, coupled with comprehensive technical services, we can provide strong equipment support for the development of modern agriculture in India.