- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does a professional PE drainage board production line ensure the quality of building drainage systems?

2025-11-13

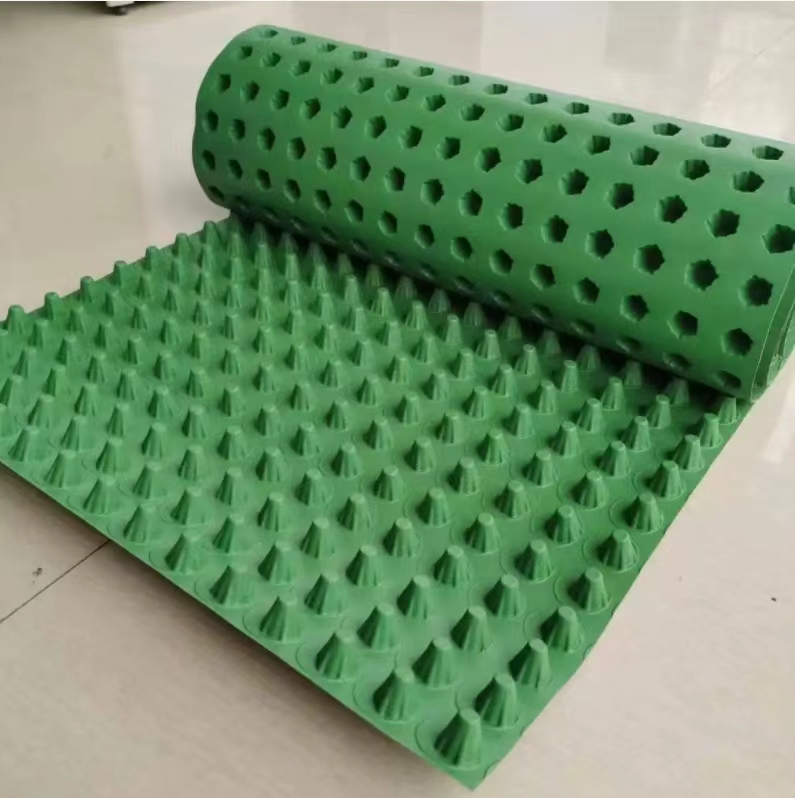

We provide the building construction industry with a professional PE drainage board production line solution. This equipment is specifically designed for producing 1500mm wide polyethylene drainage boards. The PE drainage board equipment uses a 105/33 single-screw extruder as its core, equipped with a 1650mm coat hanger die and a two-roll forming device, achieving a stable output of 250-280kg/h. This drainage board production line, proven in the market for a long time, continues to provide reliable drainage material production equipment for the building drainage field.

The core extrusion system of this PE drainage board production line adopts an optimized screw design with a screw diameter of 105mm and a length-to-diameter ratio of 33:1, specifically optimized for the characteristics of PE raw materials. The extruder is equipped with a 90KW drive motor, achieving precise speed regulation through an ABB frequency converter to ensure the stability of the production process. The screw and barrel of the PE drainage board equipment are made of 38CrMoAIA material with a nitriding depth of 0.5-0.7mm and hardness reaching HV740 and HV940 respectively, ensuring the wear resistance and reliability of the equipment during long-term operation. The extruder uses ceramic heating, with a total heating power of 36KW in 6 zones, combined with a fan cooling system to achieve precise temperature control.

The die system of the PE drainage board production line adopts a coat hanger-type runner design, with a die width of 1650mm, capable of producing single-layer drainage boards with a thickness of 0.8-1.2mm. The die runner surface is chrome-plated and polished to a mirror finish, with a cavity roughness of Ra0.1um and a die lip roughness of Ra0.05um. The two-roll forming device is equipped with Φ450×1700mm rollers, with a roller surface hardness of HRC58-62 and a chrome plating thickness of 0.08mm. A special multi-runner design ensures uniform temperature. These professional configurations guarantee that the drainage board products produced by the production line have a uniform dotted structure and stable drainage performance.

The complete PE drainage board equipment also includes a hydraulic screen changer, a melt metering pump, and a 6-meter cooling bracket. The screen changer adopts a single-plate dual-station design, enabling screen changing without stopping the machine. The metering pump is 150CC and equipped with an 18.5KW motor to ensure stable melt delivery. The traction machine is equipped with Φ250×1700mm nitrile rubber rollers, driven by a 3KW motor for smooth traction. The electrical control system of the PE drainage board production line uses a Siemens S7 series PLC and operating panel, combined with Schneider low-voltage electrical appliances, to ensure reliable equipment operation.

We have equipped the PE drainage board equipment with a complete control system and winding system. The transverse cutting machine uses an ABB variable frequency motor control, equipped with a pneumatic clamping device and a Korean Autonics encoder to achieve precise length cutting. The winding machine uses friction winding, with a maximum winding diameter of 500mm, and is equipped with an automatic meter counting system. The PE drainage board production line is also equipped with a waste edge cutting device to ensure neat product edges and convenient waste collection.

This PE drainage board production line measures 26×3.5×2.8 meters and weighs 18 tons, suitable for installation in standard factory buildings. The equipment features a modular design, making operation and maintenance simple and able to meet the production needs of different customers. We provide comprehensive technical support and services for PE drainage board equipment, including installation guidance, operation training, and after-sales maintenance, ensuring customers can fully utilize the equipment's performance and produce high-quality drainage board products that meet project requirements.