- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

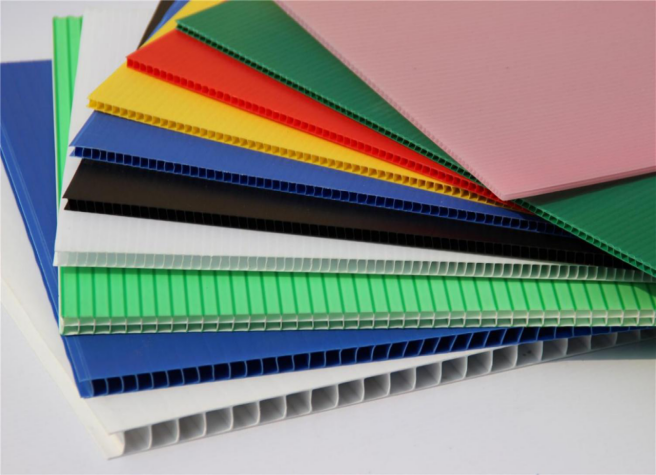

Professional PP Hollow Core Panel Production Line Provides Reliable Production Equipment for Building Waterproofing Materials

2025-11-09

We continuously provide professional PP hollow core panel production line solutions for the building waterproofing industry. This mature equipment is specifically designed for producing 2000mm wide hollow core panel waterproofing boards. The PP hollow core panel equipment uses an SJ120X36 dedicated extruder as its core, equipped with a 2200mm hollow core panel die head, achieving a stable output of 300-400kg/h. This long-term market-proven hollow core panel production line continues to provide reliable board production equipment for the building waterproofing field.

The core extrusion system of this PP hollow core panel production line adopts a dedicated screw design with a screw diameter of 120mm and a length-to-diameter ratio of 36:1, specifically optimized for the high filling characteristics of PP raw materials and recycled materials. The extruder is equipped with a 132KW main motor, achieving precise speed regulation through an INVT frequency converter, with a maximum speed of 90rpm. The screw and barrel of the PP open-cell grid panel equipment are made of 38CrMoAiA material with dual alloy wear-resistant treatment and a nitriding layer depth of 0.5-0.7mm, ensuring wear resistance and service life when processing high-filling raw materials.

The mold system of the PP open-cell grid panel production line is made of high-quality mold steel, with a mold opening width of 2200mm, capable of producing open-cell grid panels with a thickness of 2-6mm. The mold is equipped with an 11-zone heating system with a heating power of 4KW/zone, using internal heating to ensure uniform temperature. The vacuum shaping and cooling platform adopts a combination design of two-stage vacuum cooling and shaping plus one-stage cooling and shaping, equipped with a 15KW vacuum pump to ensure stable sheet forming. These professional configurations ensure that the products produced by the open-cell grid panel production line have a uniform grid structure and stable dimensional accuracy.

The entire PP open-cell grid panel equipment also includes a dual-station hydraulic screen changer, a leveling oven, and a powerful air-cooling device. The first traction machine is equipped with 6 pairs of 12 rubber rollers, each with a roller surface size of ¢250x2300mm, driven by a 7.5KW motor. The leveling oven has a temperature control range of 40℃-150℃, divided into 16 zones to ensure the flatness of the boards. The PP hollow board production line is also equipped with a transverse cutting machine and a stacking platform to achieve automated production.

We have equipped the PP hollow board equipment with a complete auxiliary system to ensure continuous production. The dual-station hydraulic screen changer is equipped with a 2.2KW hydraulic station, enabling screen changing without stopping the machine. The powerful air cooling device is equipped with 18 industrial fans with a total power of 4.5KW to ensure sufficient cooling of the boards. The second traction machine uses a worm gear reducer and servo motor drive, with a power of 3KW, forming a complete traction system with the first traction machine.

This PP hollow-panel production line measures 30×4.5×3 meters, with a total power of approximately 380KW and actual power consumption of approximately 220KW, demonstrating excellent energy efficiency. The equipment is designed to operate at a speed of 1-7 meters per minute, which can be flexibly adjusted according to production needs. We provide comprehensive technical support and services for PP hollow-panel equipment, including installation guidance, operation training, and after-sales maintenance, ensuring customers can fully utilize the equipment's performance.