- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

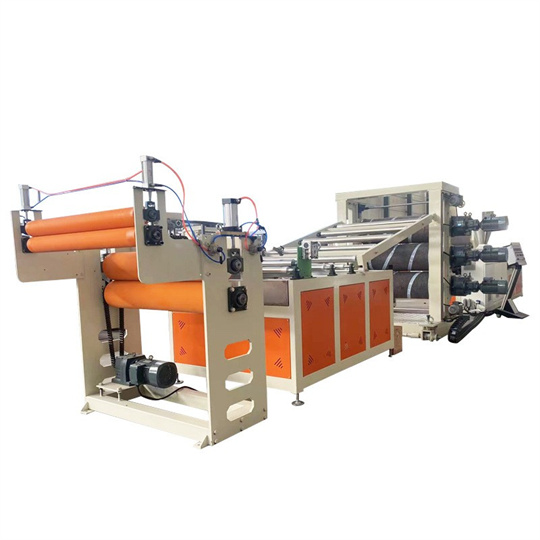

China Manure Removal Belt Extrusion Line, PP/PE sheets,manufacturer, production line, PP, PE, conveyor systems, poultry, livestock, automated Manufacturers, Suppliers, Factory

Our solutions are greatly recognized and reliable by customers and will fulfill continuously altering financial and social requirements for Manure Removal Belt Extrusion Line, PP/PE sheets,manufacturer, production line, PP, PE, conveyor systems, poultry, livestock, automated, Our enterprise warmly welcome close friends from everywhere in the environment to go to, examine and negotiate organization.

Manure Removal Belt Extrusion Line, PP/PE sheets,manufacturer, production line, PP, PE, conveyor systems, poultry, livestock, automated, With good quality, reasonable price and sincere service, we enjoy a good reputation. Items are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

Hot Products

PP/PC Lamp Case Production Line

Defects of The PP/PC lamp case production line : 1. The PP/PC lamp case production line suitable for the collision of rigid pipes and special-shaped materials; the specific configuration depends on different origins Product design plan! 2. The PP/PC lamp case production line Applicable raw materials: PC, PMMA, ABS, rigid PVC, PP, PE and other pellets 3. The PP/PC lamp case production line Applicable pipe diameter range: round pipes, semicircles, and special-shaped products within OD120mm. 4. The PP/PC lamp case production line Suitable for brazing and two-color through co-extrusion extruder and mold. 5. The PP/PC lamp case production line Different products can adopt water-cooling, cold-top, air-cooling and other processesPvc Crystal Plate Equipment

Pvc Crystal Plate Equipment can produce PVC transparent plastic sheets with a width of 800-1200 mm and a thickness of 0.8-5 mm.Nursery Tray Seeding Making Machine

Nursery Tray Seeding Making Machine technical parameter Specification width of used sheet: 300~320mm, thickness: 0.8~2mm. Forming area (maximum): 400*600 mm, working efficiency of 15~20 times / minute. Power used: three-phase four-wire 380 volts, maximum power 25KW Hydraulic pressure: 100T External size (mm) length, width and height) 3600mm*980mm*1500mmHDPE Sheet Geogrid Equipment

HDPE Sheet Geogrid Equipment is used to produce geocells. The first step of this product is to produce sheets, and then the sheets are cut online, and then the plastic sheets are connected through ultrasonic welding and other methodsPE Aluminum-plastic Board Equipment

Qingdao Eaststar Star Plastic Machinery Co., Ltd. is the first and so far the only PE Aluminum-plastic Board Equipment manufacturer. We welcome friends from all over the world to visit our factory and purchase equipment.High Quality Aluminum Plastic Panel Recycling Equipment

Qingdao East Star Plastic Machinery Co., Ltd. is mainly engaged in sheet material extruder equipment. High Quality Aluminum Plastic Panel Recycling Equipment is one of the important products produced by our company. We can match the equipment with corresponding output according to customer requirements. Friends from all over the world are welcome to purchase equipment.