- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Professional PVC Rigid Sheet Production Line: Producing High-Quality Sheets for the Garment and Building Materials Industries

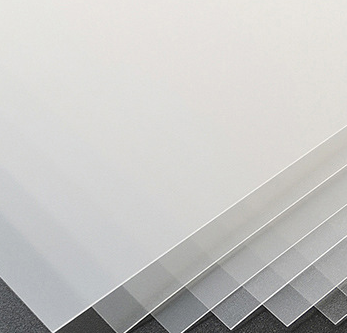

Nowadays, many people use PVC rigid sheets for clothing linings, luggage dividers, and even translucent panels for garages and greenhouses because they are rigid, durable, and easy to process. To produce even higher-quality sheets, we at Qingdao Eaststar have specifically developed this PVC rigid sheet production line. It can produce sheets up to 940 mm wide, with uniform thickness and an exceptionally smooth surface – guaranteeing reliable quality!

The core of the entire PVC rigid sheet production equipment is a twin-screw extruder, specifically designed for processing PVC materials. It can stably produce 200-300 kilograms per hour, offering high efficiency. From mixing to extrusion and molding, the entire process is automated and easy to operate.

For precise sheet dimensions and a bright surface, the die head and calendering rollers are crucial. Our PVC rigid sheet equipment use a suspended mirror-finish die head, polished to a mirror-like finish internally to ensure uniform plastic flow. The calendering rollers are also high-hardness mirror-finish rollers, combined with a temperature control system, resulting in very flat sheets. Following this are a cooling table, automatic traction, and a cutting machine, completing cooling, length cutting, and conveying automatically.

This PVC rigid sheet production line is designed with practicality in mind. It avoids flashy, impractical features, focusing on the actual production needs of PVC rigid sheets at every stage. We pay particular attention to temperature control accuracy and mechanical stability – after all, these are the most critical factors for producing high-quality sheets. Furthermore, the equipment is made with robust materials, requires minimal maintenance, and is very easy to use.

PVC rigid sheets produced with our PVC skylight panel production line are rigid and flat, making them highly versatile and suitable for many applications:

- Clothing and Footwear: Used as linings for suits, jackets, and shoe toes, providing shape and preventing deformation.

- Bags and Luggage: Used as dividers in suitcases, lightweight yet strong and resistant to pressure.

- Architectural Lighting: With slight processing, they can be made into corrugated or trapezoidal translucent panels for garages and greenhouses.

- Advertising and Display: With a smooth surface, they can be directly used for printing or screen printing, making them ideal for display boards and signs.

Qingdao Eaststar provides a complete solution, from raw materials to finished product cutting – a one-stop service. Have special requirements? We can also customize solutions for you! We also provide comprehensive training and long-term support to ensure you master the technology, helping you create high-quality products and seize more opportunities in markets such as garment accessories, packaging, and building materials.