- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does a TPE-SBS waterproof membrane production line ensure stable production of building waterproofing materials?

2025-11-05

We continuously provide professional TPE-SBS waterproof membrane production line solutions for the building waterproofing industry. This mature equipment is specifically designed for producing 1000mm wide waterproof membrane materials.

The TPE-SBS waterproof membrane equipment uses an SJ-90/33 single-screw extruder as its core, equipped with an 1160mm coat hanger die, achieving a stable output of 120-180kg/h. This long-term market-proven waterproof membrane production line continues to provide reliable material production equipment for the building waterproofing field.

The core extrusion system of this TPE-SBS waterproof membrane production line adopts a single-screw design with a screw diameter of 90mm and a length-to-diameter ratio of 33:1. The screw and barrel are made of 38CrMoAL nitrided steel, with hardnesses reaching HV950 and HV1050 respectively.

The extruder is equipped with a 75KW main motor, achieving precise speed regulation through a WEIC or INVT frequency converter. The heating system of the TPE-SBS waterproof membrane equipment uses cast aluminum or ceramic heating, with a total power of 30KW, coupled with forced cooling by a fan to ensure precise and stable temperature control.

The mold system of the TPE-SBS waterproof membrane production line adopts a coat hanger-style flow channel design, with a mold width of 1160mm, capable of producing waterproof membranes with a thickness of 0.5-2mm.

The mold is equipped with a 7-zone heating system, and the flow channel surface is chrome-plated and polished to a mirror finish. The three-roll calender is equipped with ∮400×1200mm mirror rollers, with a roller surface hardness of HRC58-62 and a chrome plating thickness of 0.08mm. A special multi-channel design ensures uniform temperature. These professional configurations guarantee that the waterproof membrane produced by the production line has a uniform thickness and a dense internal structure.

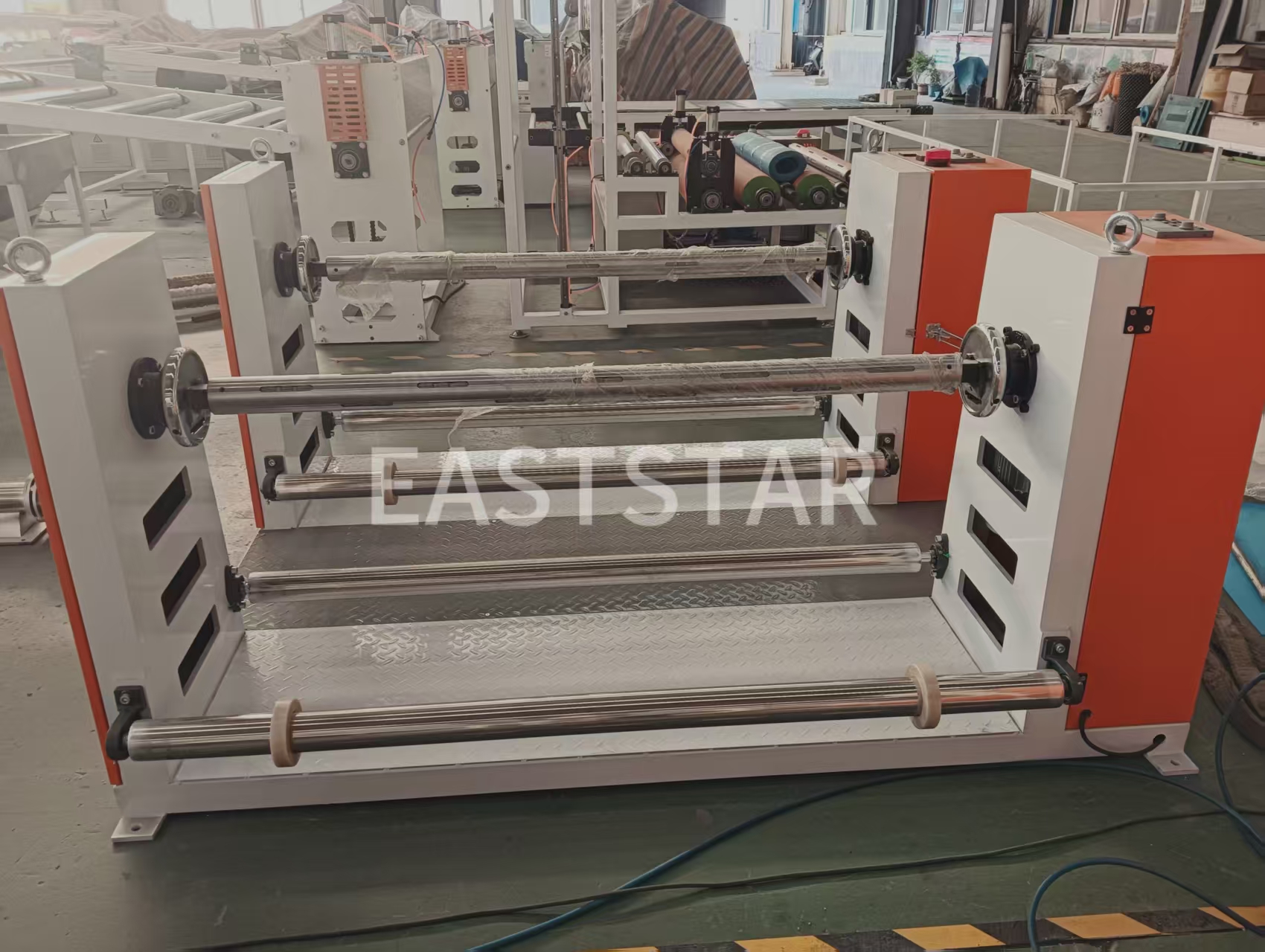

The entire TPE-SBS waterproof membrane equipment also includes a hydraulic screen changer, a 6-meter cooling bracket, a traction machine, and a tilting double-station winding system.

The traction machine is equipped with ∮240×1200mm nitrile rubber rollers, achieving precise traction through 2.2KW frequency converter control. The winding system uses constant tension frequency converter control, with a maximum winding diameter of 500mm. The electrical control system of the TPE-SBS waterproof membrane production line uses high-quality components such as Omron temperature controllers and Siemens contactors to ensure reliable equipment operation.

We have equipped the TPE-SBS waterproof membrane equipment with a complete temperature control system and unwinding device.

The roller temperature control system uses softened clean water as the medium, with a temperature control accuracy of ±1℃, and is equipped with a 2.2KW hot water pump and three sets of 9KW heaters. The dual-station unwinding device is equipped with a pneumatic shaft and tension control system to achieve continuous production. The waterproof membrane production line is also equipped with an edge trimming device and a waste edge winding system to ensure neat product edges.

This TPE-SBS waterproof membrane production line has overall dimensions of 26×2×2.2 meters and a total weight of 14.8 tons, suitable for installation in a standard factory building.

The equipment is designed with a linear speed of 1-8 m/min, which can be flexibly adjusted according to production needs. We provide comprehensive technical support and services for TPE-SBS waterproof membrane equipment to ensure that customers can fully utilize the equipment's performance and produce high-quality waterproof materials that meet national standards.