- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

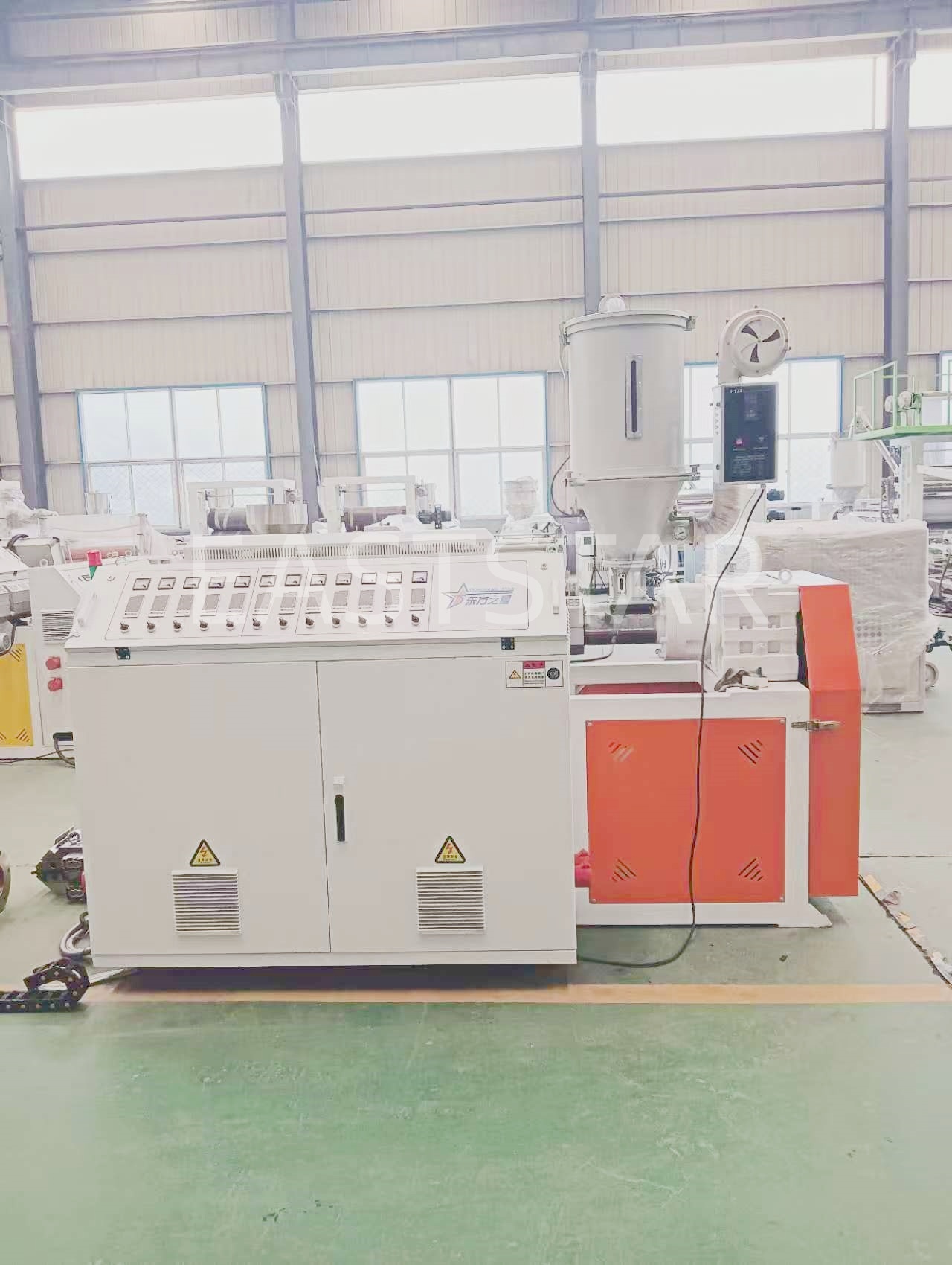

EASTSTR Advances POK Sheet Production with Innovative High-Performance Extrusion Line

2025-10-19

Recently, EASTSTR, a leading manufacturer of polymer processing equipment, announced that its sheet extrusion line designed specifically for polyketone (POK) materials has achieved a major technological breakthrough and has been successfully delivered to multiple customers. This innovative solution is significantly improving POK sheet production efficiency and end-product quality.

As an emerging, high-performance bio-based engineering plastic, POK is rapidly becoming an ideal material for industries such as packaging, automotive, and electronics due to its excellent impact resistance, abrasion resistance, gas barrier properties, and chemical stability. However, its unique processing characteristics also place extremely high demands on the stability and precision control of extrusion equipment.

To address these challenges, EASTSTR's engineering team has thoroughly optimized the extruder's screw configuration, temperature control system, and die design. The new POK sheet extruder ensures excellent plasticization and thermal stability during processing, resulting in the production of high-quality POK sheet with high surface gloss, uniform thickness, and consistent mechanical properties.

"Market demand for sustainable, high-performance materials continues to grow, and POK is a leading example," said EASTSTR's Chief Technology Officer. "Our goal is to provide customers with cutting-edge equipment that not only processes POK but also maximizes its exceptional properties. This new extrusion line embodies that commitment."

The equipment's high output and low energy consumption also provide significant economic benefits to customers, further strengthening POK's competitive advantage over traditional engineering plastics. This successful rollout demonstrates EASTSTR's technological leadership in specialty polymer processing equipment and provides strong equipment support for innovation in downstream application markets.